TM 11-6625-539-15-2

TROUBLESHOOTING

AND

REPAIR

NOTE

Voltmeter, Electronic ME-30(*)/U repre-

a. General, The first procedure in servicing a

sents Voltmeter, Meter ME-30A/U and

defective test set is to sectionalize the fault.

Voltmeters, Electronic ME-30B/U, ME-

Sectionalization consists of tracing the fault to a

30/U, and ME-30E/U.

group of circuits concerned with one test function.

Once the defective function is found, isolation to the

defective part is accomplished. Troubleshooting is

performed by general support and depot repairmen.

b. Sectionalization. Listed in (1) and (2) below is a

group of tests that are arranged to help locate the

defect to a faulty component.

(1) Visual inspection. When the test set is

brought in for repair, remove the front panel and

inspect as follows:

(a) Check to see that all connections are properly

seated. Repair or replace any connections or leads

that are broken or otherwise defective.

(b) Check all switches and controls for ease of

operation.

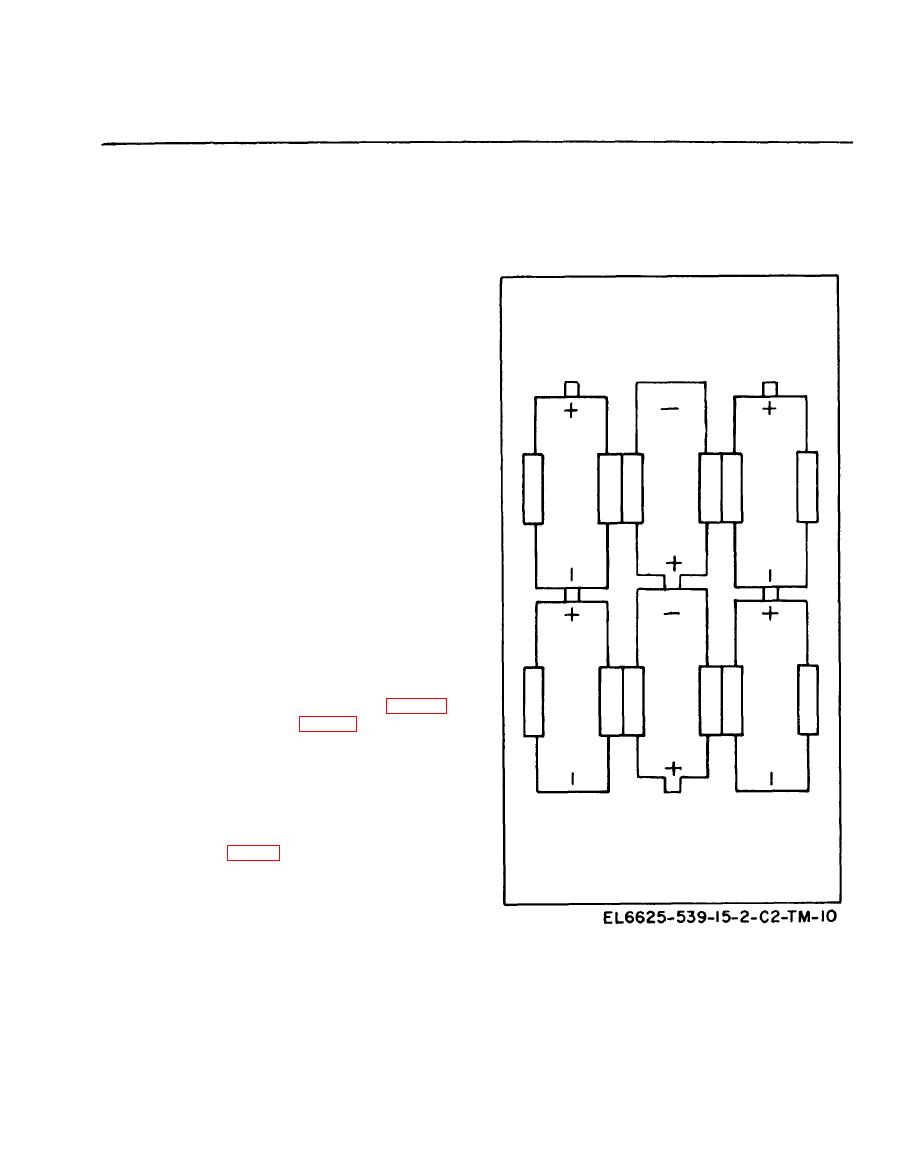

(c) Remove the access cover to the batteries, and

check for corrosion and looseness of batteries.

(d) Inspect for loose or missing screws, specifi-

cally those that fasten the rear parts board in place.

(2) Operational tests. Operational tests fre-

quently indicate the general location of trouble. In

many instances, the test will determine the exact

nature of the fault. The operator's preventive

maintenance checks and operation check (para 4-4)

and the alignment procedures (para 7-1 through 7-4)

provide a good operational test.

(3) Troobleshooting chart and equipment re-

quired. The meter indications, or lack of meter

indications, and operational checks provide a sys-

tematic method of localizing trouble to the faulty

circuit. The trouble symptoms listed in the troub-

leshooting chart (para 6-2) provide additional infor-

mation for localizing troubles. The only test equip-

ment required is Voltmeter, Electronic ME-30(*)/U

(TM 11-6625-320-12).

Change 2 6 - 1