TM 11-6625-539-15-2

Maintenance

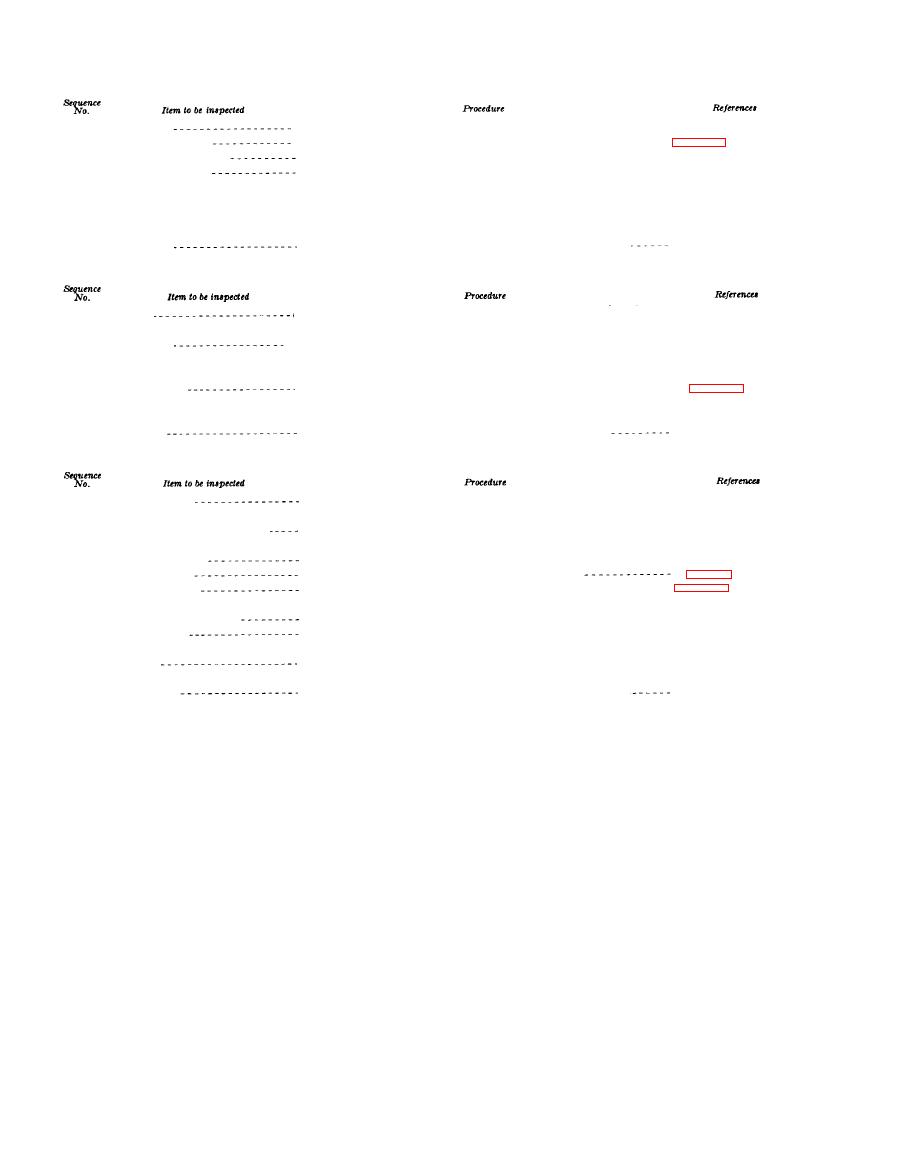

Checks

and

Service

Chart

Check equipment for completeness and general condition . . . . . App B.

1

Test

set

Clean exterior surfaces of the equipment . . . . . . . . . . . . . . . ---- Para 4-7.

2

Exterior

surfaces

Inspect external receptacles for breakage and looseness . . . . . . .

3

External

Inspect

front

panel

glass

window

for

damaged

housing,

broken

4

Meter

glass

glass, physical damage, dust, or moisture.

During

operation

(sequence

No.

6),

check

knobs,

controls,

and

5

Knobs,

controls,

and

switches__

switches

for

proper

mechanical

action.

Action

must

be

positive,

without

backlash,

binding,

or

scraping.

During operation, be alert for any abnormal indications

6

Operation

1 Cables

Inspect external cables for cuts, cracked or gouged jackets,

fraying,

or

kinks.

2 Hardware

Inspect all exterior hardware for looseness and damage. The

test

set

cover,

carrying

handle,

latches,

and

all

bolts

and

screws must be tight and not damaged.

3 Preservation

Inspect equipment for bare spots, rust, and corrosion. If these Paras 4-7 and 4-8.

conditions

exist,

refer

to

a

higher

maintenance

category

for

repair.

4 Batteries

Inspect batteries for leakage, corrosion, and swelling

Inspect

the

manual

for

and

usable

condition.

Be

DA

Pam

310-4.

1

Publications

sure that all changes to the manual are on hand.

Check

to

see

that

all

URGENT

MWO's

have

been

applied

and

DA

Pam

310-7.

2

Modification

work

orders

that

all

NORMAL

MWO's

have

been

scheduled.

Check

the

equipment

for

completeness

and

general

condition__

App

B.

3

Completeness

Clean the exterior surfaces of the equipment

4

Cleanliness

Inspect the equipment to determine that it is free of bare spots, Para 4-8.

5

Preservation

rust,

and

corrosion.

Inspect

the

external

receptacles

for

breakage

and

looseness_

_

_

External

receptacles

6

Inspect

the

front

panel

glass

for

damaged

housing,

broken

7

Meter

glass

glass,

physical

damage,

dust,

or

moisture.

Inspect

the

external

cables

for

cuts,

cracked

or

damaged

8

Cables

jackets,

fraying,

or

kinks.

During

operation,

be

alert

for

any

abnormal

indication

9

Operation

Caution: Do not press on the meter face (glass)

4-7. Cleaning

when cleaning; the meter may become damaged.

Inspect the exterior surface of the test set. The ex-

d. Clean the front panel, meter, and control knobs;

terior surface should be free of dirt, grease, and

use a soft, clean cloth. If necessary, dampen the cloth

fungus.

with water; mild soap may be used for more effective

a. Remove dust and other loose dirt with a clean,

cleaning.

SOft cloth.

Warning: Prolonged breathing of cleaning

a. Rustproofing. When the finish on the test set has

compound is dangerous; make certain that ade-

become badly scarred or damaged, rust and corrosion

quate ventilation is provided. Cleaning compound

can be prevented by touching up the bare spots. Use

is flammable; do not use near a flame. Avoid con-

No. 000 sandpaper to clean the surface down to the

tact with the skin; wash off any that spills on

bare metal. Obtain a bright, smooth finish.

your hands.

b. Painting. Remove rust and corrosion from mental

b. Remove grease, fungus, and ground-in dirt from

surfaces by lightly sanding them with fine sand-

the cases; use a cloth dampened (not wet) with clean-

paper. Brush two thin coats of paint on the bare metal

ing compound (FSN 79303959542).

to protect it. Refer to the applicable cleaning and re-

c. Remove dirt from plugs and jacks with a brush.

finishing practices specified in TB SIG 364.