TM 55-4920-231-14

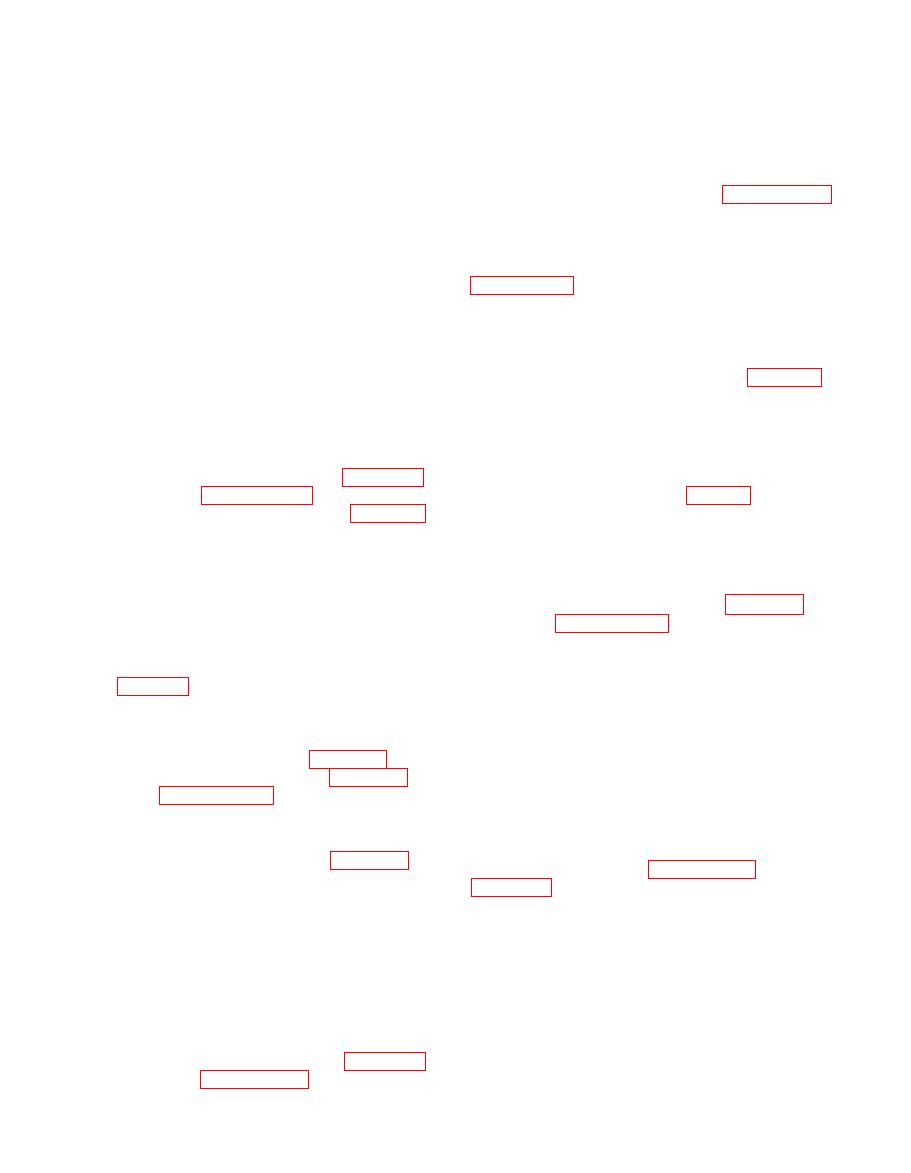

PART NO.

INSTRUMENT

their removal from the tester, in a manner simi-

lar to that used in testing a remote instrument.

Manifold Pressure Gage

AN 5770-5

(MS 28077-5)

Refer to the applicable technical manual for the

MS 28061-1

Fuel Pressure Gage

particular instrument for range of accuracy in

calibrating.

97. OIL RESERVOIR.

b. Repair. Accomplish repair of instruments

Remove, disassemble, clean, and inspect the

in accordance with the applicable technical man-

reservoir assembly as outlined in paragraph 77.

Repair of the reservoir consists primarily of the

uals for the part numbers as listed below.

replacement of defective parts as a consequence

INSTRUMENT

PART NO.

of inspection and observance of function. Reas-

MS 28049

Rate-of-climb Indicator

semble and install the reservoir as outlined in

Altimeter

MS 28044-1

Airspeed Indicator

MS 28021-1

Section V. ELECTRICAL SYSTEM

(2) Unsolder wiring harness (4, figure 25)

leads from terminals on transformer (46).

Remove electrolytic filter capacitor (2, figure

(3) Remove nuts (21), lockwashers (22),

24) from chassis (20) for replacement as fol-

and screws (35), securing transformer (46) to

lows:

chassis (51), and remove transformer.

a. Removal.

c. Installation.

(1) Remove chassis assembly (figure 24)

from tester case (paragraph 73a).

(1) Place transformer (46, figure 25) in po-

sition on chassis (51) and secure with screws

(2) Unsolder wiring harness (4, figure 25)

leads from terminals on capacitor (43).

(35), lockwashers (22), and nuts (21).

(3) Remove nuts (39), terminal (40), and

(2) Solder wiring harness (4) leads to ter-

minals on transformer (46) as indicated in fig-

screws (41 ) securing bracket (44) and ground

leads to chassis (51).

ure 10.

(3) Install chassis assembly (figure 24) in

(4) Remove capacitor and bracket assembly

(42).

tester case (paragraph 73c).

d. Test.

b. Installation.

(1) Insert a Variac or an equivalent varia-

(1) Place capacitor and bracket assembly

ble transformer in the primary circuit of the

(42, figure 25) in position on chassis (51), in-

transformer and set the input at 115 volts.

sert screws (41), install ground leads and termi-

(2) Provide a test setup having a load suf-

nal (40), and secure with nuts (39).

ficient to cause a 2.2 ampere flow of current in

(2) Solder leads to terminals on capacitor

the secondary circuit.

(43) as identified, or refer to figure 10.

(3) Check the voltage across the secondary

(3) Install chassis assembly (figure 24) in

output. It should be approximately 26 volts.

tester case (paragraph 73c).

99. TRANSFORMER.

Remove, clean, and inspect motor and pump

The stepdown transformer (6, figure 24) is

assembly as directed in paragraph 81 and, using

inspected, replaced, and tested as follows:

a. Inspection.

perform the procedures which follow:

(1) Inspect transformer for signs of exces-

a. Inspection. At disassembly, inspect

sive heat such as melted solder or wax, burned

insulation, and odor of burned materials.

motor and pump assembly as follows:

(2) Check terminal to see that connections

(1) Check resistance between motor input

are tight.

leads and ground. Reading should be approxi-

(3) Check leads for shorted or bare wires.

mately 1.7 ohms.

(2) Check field windings for continuity,

b. Removal. If it is necessary to replace the

transformer, proceed as follows:

grounds, and shorts.

(1) Remove chassis assembly (figure 24)

(3) Examine bearings for excessive wear

from tester case (paragraph 73a).

and other defects.