TM 55-4920-231-14

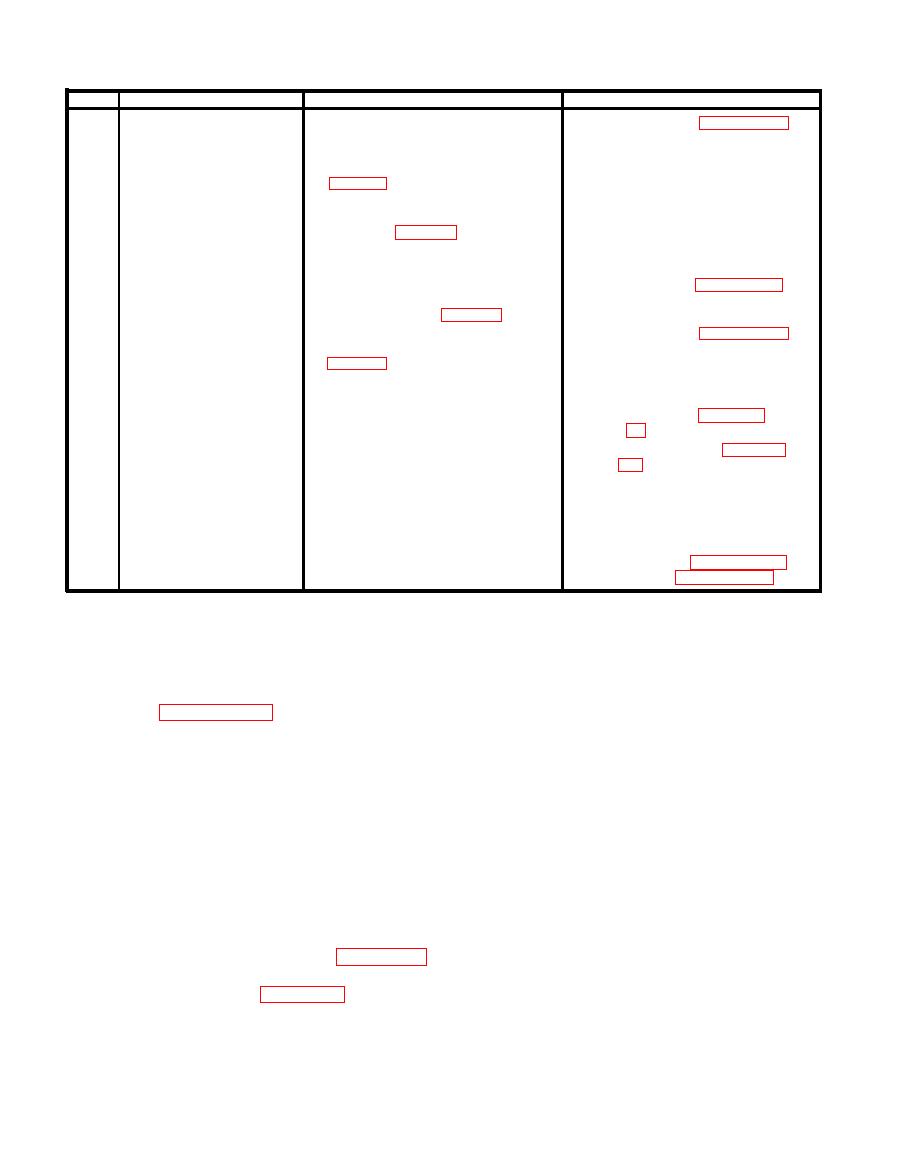

Table 6. Troubleshooting (Cont).

Item No.

Trouble

Probable Cause

Possible Remedy

If zero voltage, disconnect a lead from

Replace transformer (paragraph 99).

terminal 3 or 4 and recheck

volage; if still zero, trans-

former is defective. (See

2

Fuse blows when power

Repair or replace motor (para-

Short in electric motor.

switch is placed in ON

(Check continuity and for

graphs 81 and 100).

position.

shorts; see figure 10.)

AC OPERATION ONLY

Shorted transformer primary

Replace transformer (paragraph 99).

windings. (Check for continuity

and for shorts, see figure 10.)

3

Indicator light illuminates

Shorted transformer. (Check

Replace transformer (paragraph 99).

but motor does not run.

continuity and far shorts; see

Open lead in motor. (Check for

Repair or replace motor (para-

continuity.)

graphs 81 and 100).

Defective motor.

Repair or replace motor (para-

graphs 81 and 100).

Armature defective.

Repair or replace armature (para-

graph 100) .

Open circuit in motor armature or

Repair or replace motor (para-

graphs 81 and 100).

field winding. (Check re-

sistance between motor input

and ground-should be ap-

proximately 1.7 ohms.)

Repair commutator (paragraph 100).

4

Motor runs slowly.

Commutator worn or dirty.

Replace bearings (paragraph 100).

Defective motor bearings.

Section III. TESTER UNIT

91. TESTER CALIBRATION.

93. TESTER REPLACEMENT.

Calibration of the individual instruments as

If the unit becomes damaged beyond repair, or

described in paragraph 96 accomplishes the cali-

if a nonremediable malfunction develops, replace

bration of the tester.

the unit.

94. TESTER REPAIR.

Testing the instruments and components indi-

Repair of the individual instruments and com-

vidually accomplishes the testing of the unit

ponents as outlined throughout this manual ac-

(paragraphs 39 through 44).

complishes repair of the unit.

Section IV. PNEUMATIC SYSTEM

during disassembly and inspection procedures

95. VALVES.

outlined in the paragraphs stated above.

Inspection, testing, cleaning, and replacement

of valves is accomplished as stated in paragraphs

96. INSTRUMENTS.

39, 52e, 61 through 64, 71, 72, 75, 76, and 78.

Under conditions specified in appendix B, para-

graph 31c, replacement of valves may be accom-

the tester by comparing its reading against a

plished by the organizational maintenance level.

standard instrument, gage, or other applicable

Repair of valves consists primarily of replace-

apparatus, Calibration of the master instruments

ment of individual defective parts as indicated

(those of tester) may be performed, without

52