TM 11-6625-2616-14

(4) The oscilloscope should indicate the

b. Test Procedure.

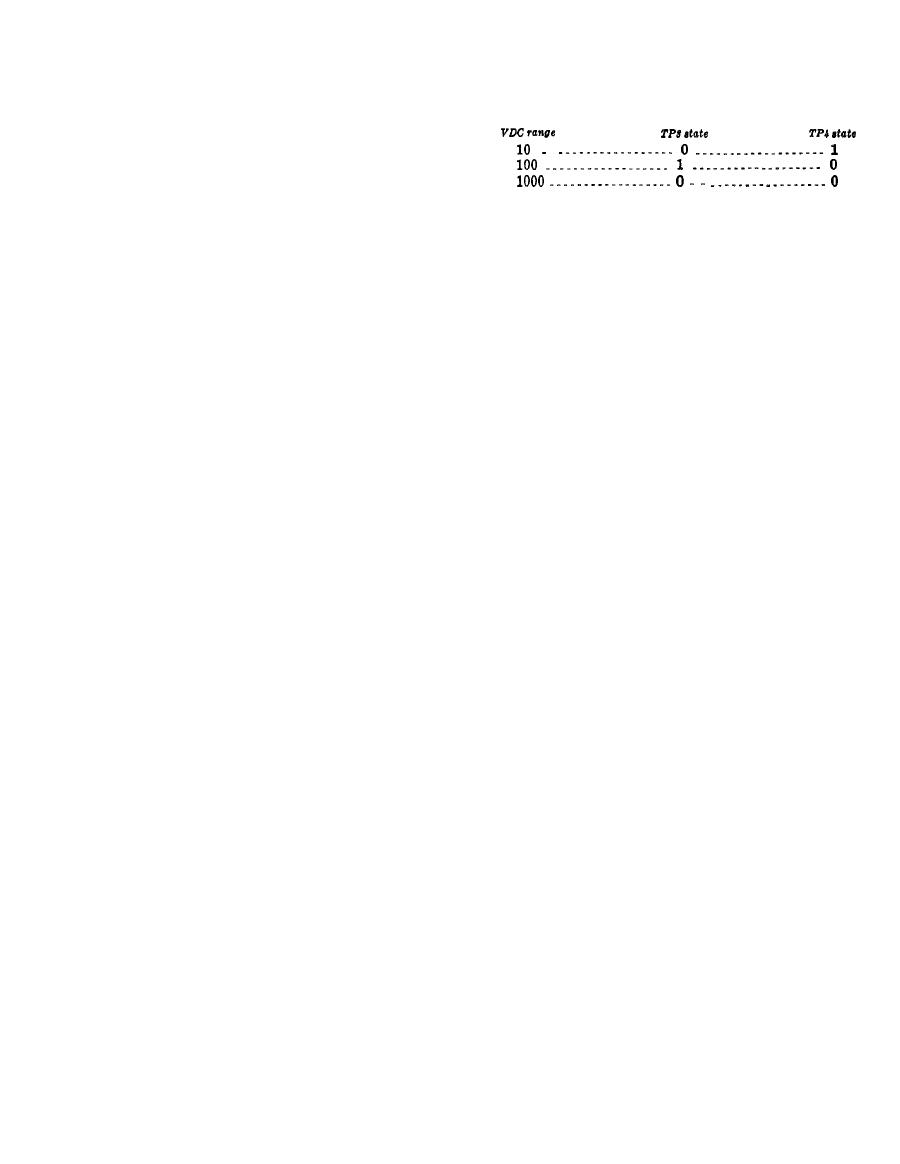

levels shown in the chart.

(1) Connect the oscilloscope common to in-

strument SIG L.

to TP3 on the main board assembly.

(3) Connect the oscilloscope 10:1 probe to

6-15. Range Change Pulse Width Test

TP2 on the main board assembly.

a. Test Conditions.

(4) The oscilloscope should indicate a 20-

(1) Instrument connected to 115 vac or 230

microsecond pulse at 3- to 5-volt amplitude from

vac power source.

0 to 240 milliseconds after the trialing edge

(2) PWR ON pushbutton in (no warmup

(negative going) of the pulse at TP3. Delay

required ).

between pulses is proportional to the input being

measured by the instrument. The pulse at TP2

(3) VDC pushbutton in.

is generated when the clock pulses at TP12

b. Test Procedure,

cease.

(1) Connect the oscilloscope common to in-

strument SIG L.

(2) Connect the voltage standard common

a. Test Conditions.

to instrument SIG L.

(1) Instrument connected to 115 vac or 230

(3) Connect the voltage standard output

vac power source.

to instrument SIG H.

(2) PWR ON pushbutton in (no warmup

(4) Connect the oscilloscope external trig-

required). VDC pushbutton in.

ger to TP2 on the main board assembly.

(5) Set the voltage standard output to

b. Test Procedure.

+5.0000 volts.

(1) Connect the oscilloscope common to in-

(6) Connect the oscilloscope 10:1 probe to

strument SIG L.

TP2 on the signal conditioning board.

(2) Connect the oscilloscope 10:1 probe to

(7) The oscilloscope should indicate a 20-

TP3 or TP4 on the signal conditioning assembly,

microsecond pulse at 3- to 5-volt amplitude coin-

(3) Actuate RNG CHNG pushbutton to

cident with the external trigger pulse whenever

place instrument in the ranges shown in the chart

a range change is required by the input to the

below,

instrument, If the input is increased from 5 volts

to 50 volts, the pulse will appear at TP2 on the

NOTE

"0" state corresponds to a voltage less

signal conditioning board. If the input is de-

creased from 50 volts to 5 volts, the pulse will

than + 0.4v and "l" state corresponds

appear at TP1.

to a voltage greater than +2.4v.