TM 55-4920-244-14

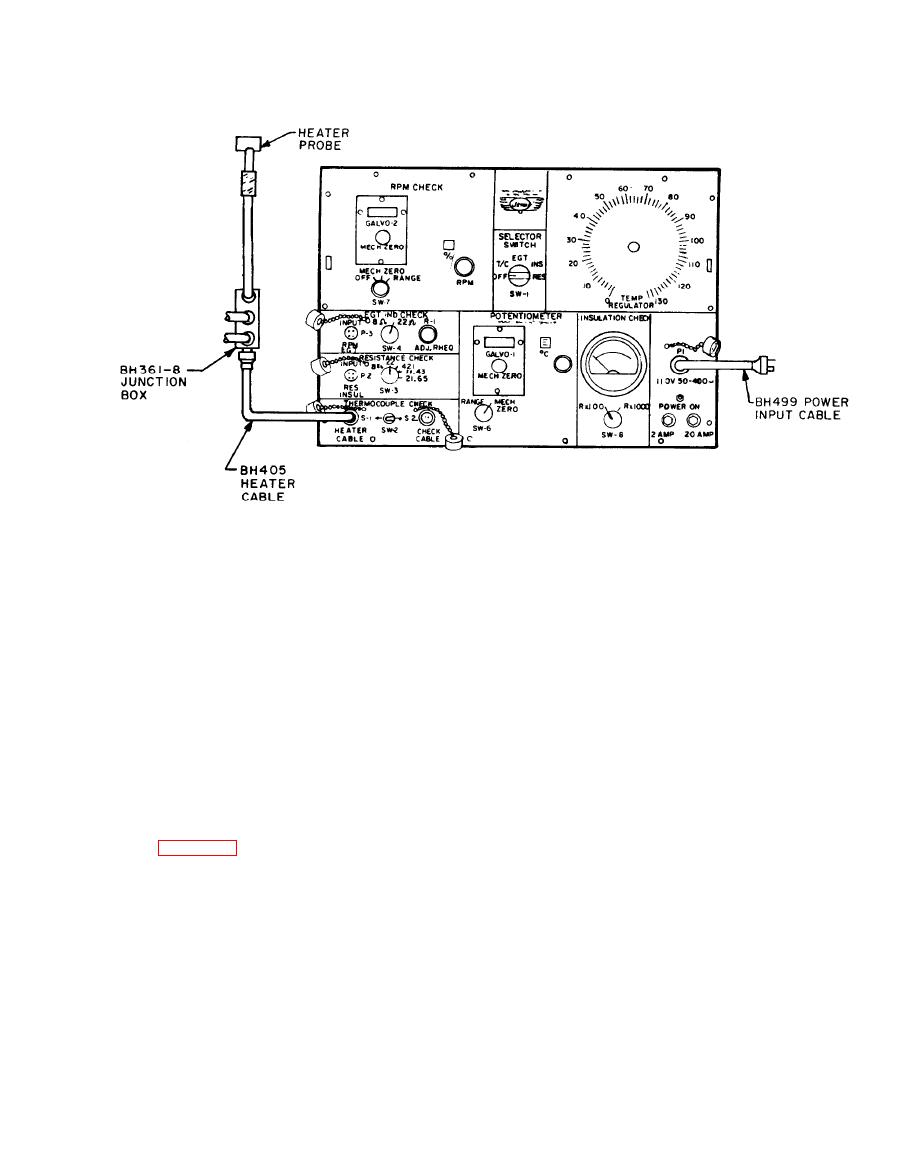

f. Place switch SW-6 in RANGE position.

that there is continuity from junction box,

through heater cable, and galvanomeer.

for deflection

g. Note galvanometers

g. Place TEMP. REGULATOR knob in 0

which indicates continuity through check cable to

position and switch SW-1 in OFF position. Dis-

galvanometers.

connect heater probe at junction box.

h. Repeat f and g above and test remain-

NOTE

ing healer probes and junction box outlets.

i. Replace any heater probe that does not

If no deflection is noted,

indicate a temperature rise on galvanometers.

make sure indication on

Replace junction box if any outlet does not indi-

o

C scale is not equal to

cate continuity.

ambient temperature.

j. Place SW-6 in MECH. ZERO position.

h. Replace check cable if galvanometers

3-14. Check Cable Circuit Continuity Check.

does not indicate continuity.

i. Place switch SW-6 in MECH. ZERO

After 10 test operations, the check cable

circuit shall be operationally checked as follows.

position.

a. Connect check cable to CHECK

j. Place switch SW-2 in SW-1 position and

CABLE connector.

remove replacement thermocouple from check

b. Insert a replacement thermocouple of

cable.

known quality in terminals A-, B+) of check

cable.

k. Remove check cable from CHECK

c. Place switch SW-1 in T/C position.

CABLE connector.

d. Place switch SW-2 in S-2 position.

l. Properly stow check cable in cable stor-

e. Place switch SW-6 in MECH. ZERO

age compartment.

position and zero galvanometers with mechanical

zero knob.

m. Secure tester after operation.