TM 55-4920-244-14

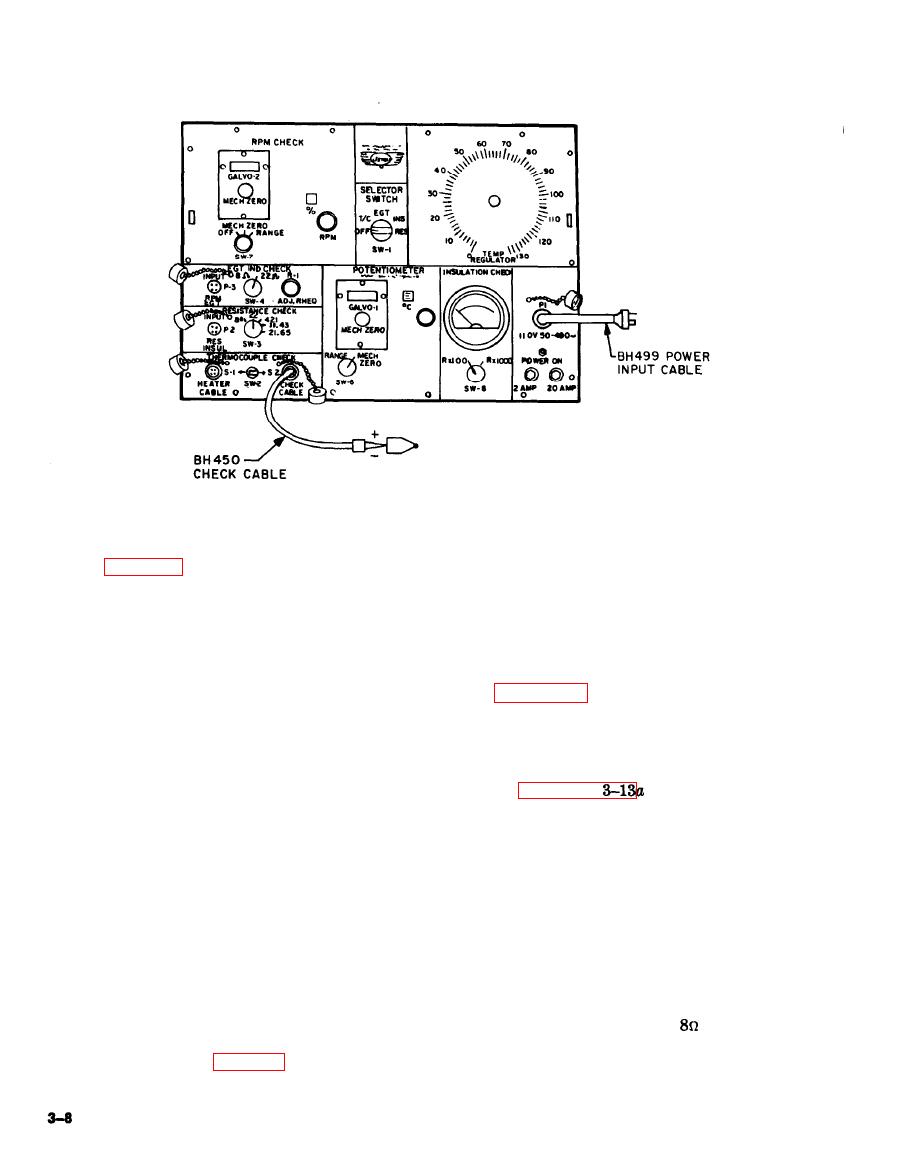

i. Place switch SW-6 in MECH. ZERO po-

3-15. Potentiometer Continuity Check.

sition.

j. Place switch SW-2 in S-1 position and

After 10 test operations, the POTENTI-

remove replacement thermocouple from CHECK

OMETER circuit shall be operationally checked

CABLE connector.

as follows:

k. Secure tester after operation.

CAUTION

3-16. EGT Indicator Circuit Operation Check.

Never use an ohmmeter or

voltmeter to check the po-

After 25 test operations, the EGT indi-

tentiometer circuit for con-

cator circuit shall be functionally checked as fol-

tinuity as damage to gal-

lows:

vanometers will result.

a. Prepare tester for operation in accord-

a. Insert a replacement thermocouple of

ance with paragraph

through c.

known quality in A (-) and B (+) sockets of

b. Connect instrument cable to egt indi-

CHECK CABLE connector.

cator check adapter and instrument cable to

b. Place switch SW-1 in T/C position.

connector P-3.

c. Place switch SW-2 in S-2 position.

c. Place switch SW-1 in EGT position.

d. Place switch SW-6 in MECH. ZERO

d. Place switch SW-6 in MECH. ZERO

position and zero galvanometers with mechanical

position and zero galvanometers with mechanical

zero knob.

zero knob.

e. Place switch SW-6 in RANGE position.

e. Place switch SW-6 in RANGE posi-

f. Apply heat to the replacement thermo-

tion.

couple.

f. Connect terminals of egt indicator check

g. With replacement thermocouple heat-

adapter together.

ing, note galvanometers for deflection which indi-

cates continuity of the potentiometer circuit.

g. Place switch SW-4 in

position.

h. If potentiometer circuit does not indi-

h. Turn potentiometer R-1 and note gal-

cate continuity, refer to Table 3-2 to locate de-

vanometers which indicates egt indicator circuit

fects.

continuity.