TM 55-4920-244-14

CAUTION

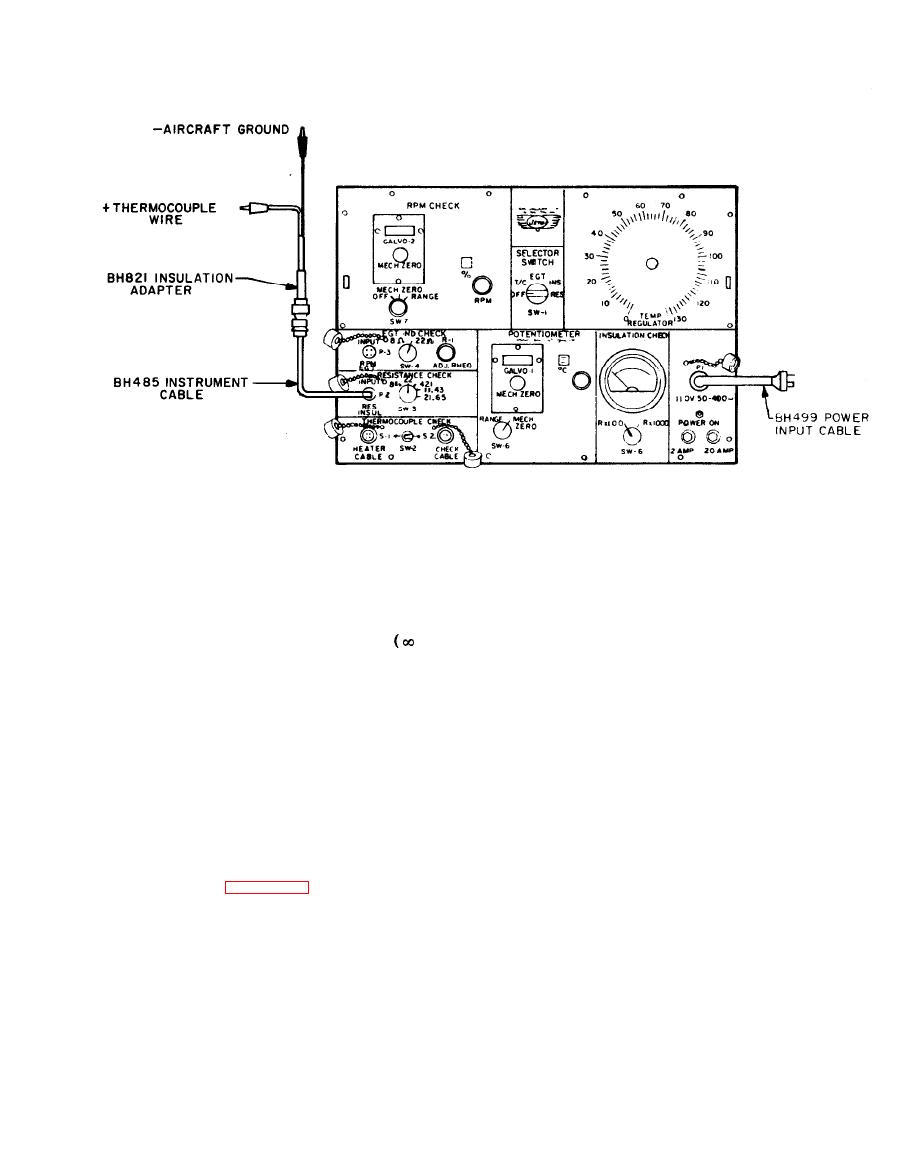

d. Place switch SW-1 in INSUL. position.

e. Place switch SW-8 in Rx1000 position.

Never

allow

continuity

f. Place insulation check adapter leads on

check probe temperature to

both thermocouple leads at aircraft EGT indi-

go above 800 Celsius (1472

cator terminals or at parallel point. Insulation

Fahrenheit).

Damage

to

check meter should read the infinite

resist-

probe could result.

ance.

g. Place switch SW-1 in OFF position.

d. Turn TEMP. REGULATOR knob to

h. Disconnect insulation check adapter

maximum and bring continuity check probe to a

from instrument cable and aircraft EGT indicator

temperature within a range of 500 to 800 Cel-

terminals.

sius (932 to 1472 Fahrenheit) as read on C

i. Disconnect instrument cable from con-

scale.

nector P-2.

e. Place switch SW-6 in MECH. ZERO

j. Properly stow instrument cable and in-

sulation check adapter in cable storage compart-

position and zero galvanometers by turning

ment.

MECH. ZERO knob.

f. Place switch SW-6 in RANGE position

Continuity Check of Thermocouple and

to take temperature readings. Adjust tempera-

Harness (Figure 2-7).

ture selector knob until galvanometers reads zero.

NOTE

Temperature reading appears on the C scale.

Indicator

must be in-

g. Check each engine thermocouple to

stalled.

eliminate any error due to one or more engine

a. Connect continuity probe to heater

thermocouples being inoperative. When using

cable.

continuity check probe, touch end of loop or

b. Connect heater cable to HEATER CA-

twisted-type thermocouple; check sampling-type

BLE connector on tester.

thermocouples by holding V-section of continuity

check probe against case of sampling-type ther-

c. Place switch SW-1 in T/C position and

switch SW-2 in S-1 position.

mocouple end. In either case, aircraft EGT indi-