b. Place switch SW-1 in INSUL. position.

NOTE

c. Place switch SW-8 in Rx1000 position.

Clean and tighten all

d. Short insulation check adapter leads to-

thermocouple harness con-

gether. INSULATION CHECK meter should

nections before adjusting

read zero.

resistance spool.

e. Place one lead of insulation check

adapter on bare thermocouple lead in aircraft

and one lead on aircraft ground. Insulation

galvanometers reads zero plus or minus appli-

check meter should read the resistance specified

cable tolerances (one division of galvanometers

for the aircraft being checked.

equals approximately 0.05 ohm). A deflection to

f. Place switch SW-1 in OFF position.

the right indicates an increase in resistance.

g. Disconnect insulation check adapter

i. Place switch SW-6 in MECH. ZERO

from instrument cable.

position.

h. Disconnect instrument cable from con-

j. Disconnect resistance check adapter

nector P-2.

from thermocouple leads and from instrument

i. Properly stow instrument cable and in-

cable.

sulation check adapter in cable storage compart

k. Disconnect instrument cable from con-

ment.

nector P-2.

l. Properly stow instrument cable and re-

sistance check adapter in cable storage compart-

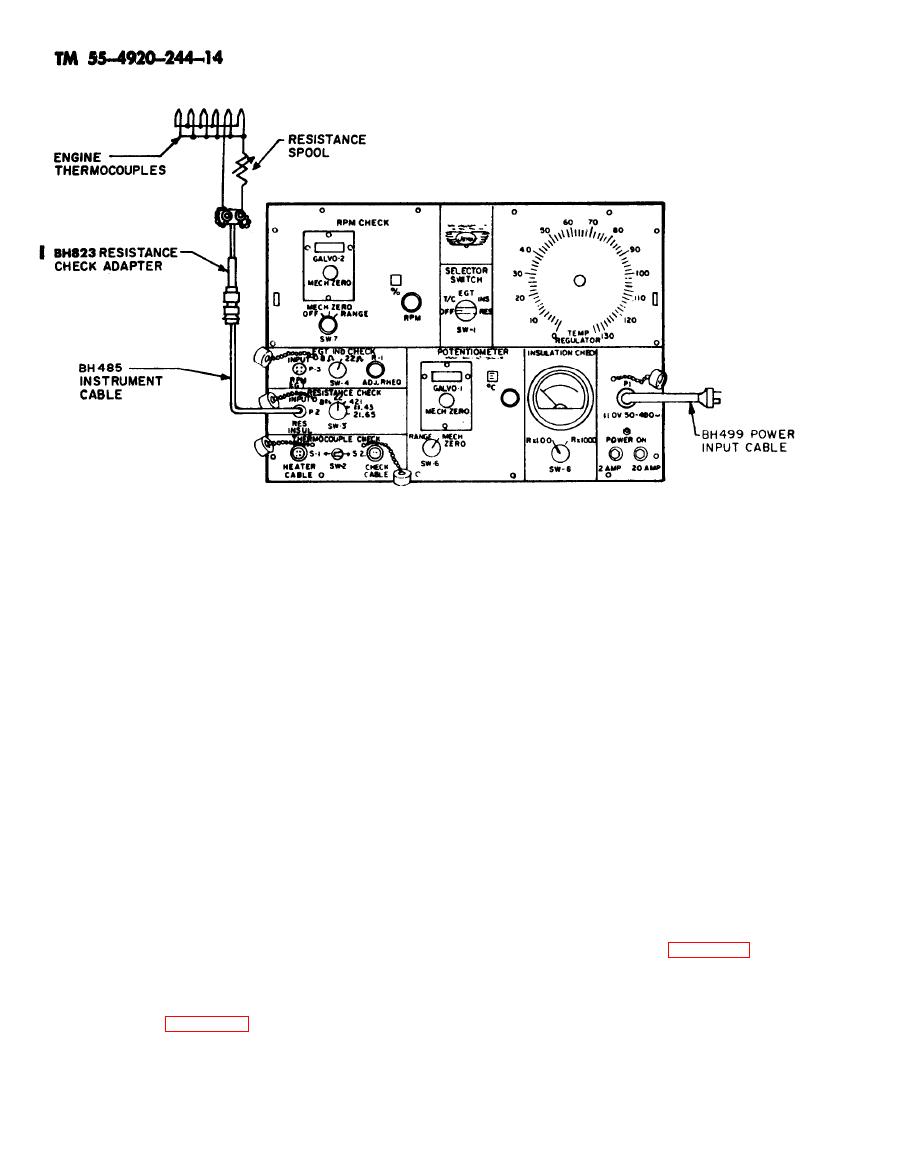

Resistance Check Circuit (Figure 2-6).

ment.

a. Remove thermocouple leads from EGT

indicator.

b. Remove thermocouple leads from en-

Ground) (Figure 2-6).

gine thermocouple harness at parallel points.

c. Connect insulation check adapter to in-

a. Connect insulation check adapter to in-

strument cable and instrument cable to connector

strument cable and instrument cable to connector

P-2.

P-2.

Change 2

2-8