(4) Continue TEMP. REGULATOR

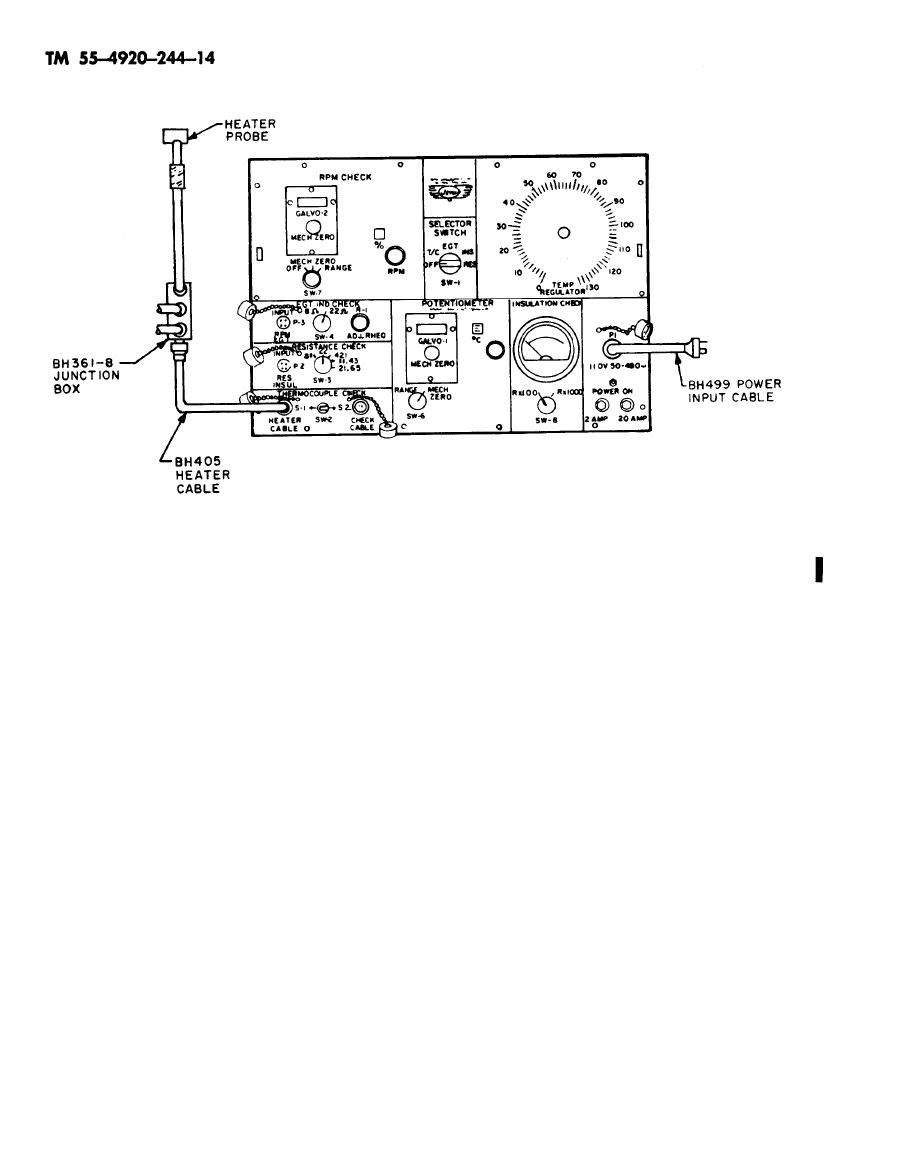

c. Place switch SW-6 in RANGE position.

knob adjustments until heater probes are

d. Perform temperature adjustments as

stabilized at test temperature.

outlined below.

NOTE

NOTE

If testing in high wind or

The following procedure

cold weather, it is advisa-

will aid the operator in

ble to place a cover over

making rapid adjustment

tail cone to reduce heat

of the temperature of the

dissipation. A tail cone

heater probes and tester

cover should always be

readings.

temperature

used when testing engines

With practice the oper-

equipped with sampling-

ator will be capable of

type thermocouples to

making rapid adjustments

maintain true temperature

of the heater probes.

over the entire length of

TEMP. REGULATOR

(1) Turn

thermocouple.

knob to maximum and allow heater probes to

heat to test temperature.

(5) With heater probes stabilized at

engine test temperature, read C scale and air-

(2) Adjust TEMP. REGULATOR

craft EGT indicator. Difference between these

knob back to allow temperature of heater probes

readings is indicated error of egt system and

to stabilize at test temperature (approximately 96

should not exceed applicable aircraft/engine

to 108 volts for 700 Celsius). Observe galva-

technical manual tolerance.

nometers for deflection and TEMP. REGULATOR

knob for voltage setting.

(6) Place switch SW-6 in MECH.

TEMP.

REULATOR

(3) Turn

ZERO position.

knob well above or below voltage setting, ac-

(7) Return TEMP. REGULATOR

cording to galvanometers deflection, for a few

knob to zero.

seconds.

2-4 Change 4