TM 11-6625-444-14-2

and described in tables 4-2 and 4-3. The item

The voltmeter shall rechecked and serviced in

accordance with tables 4-2 and 4-3.

numbers indicate the sequence of and minimum

inspection required. Defects discovered during

operation of the unit will be noted for future cor-

rection to be made as soon as operation has

ceased. Stop operation immediately if a defi-

ciency is noted during operation which would

NOTE

damage the equipment. Record all deficiencies

together with the corrective action taken on ap-

If the equipment must be kept in

plicable forms as prescribed in TM38-750. In-

continuous operation, check and

structions for performing the required checks are

service only those items that can

identified as periodic checks in this maintenance

be checked and serviced without

manual.

disturbing operation; make the com-

plete checks and services when

the equipment can be shut down.

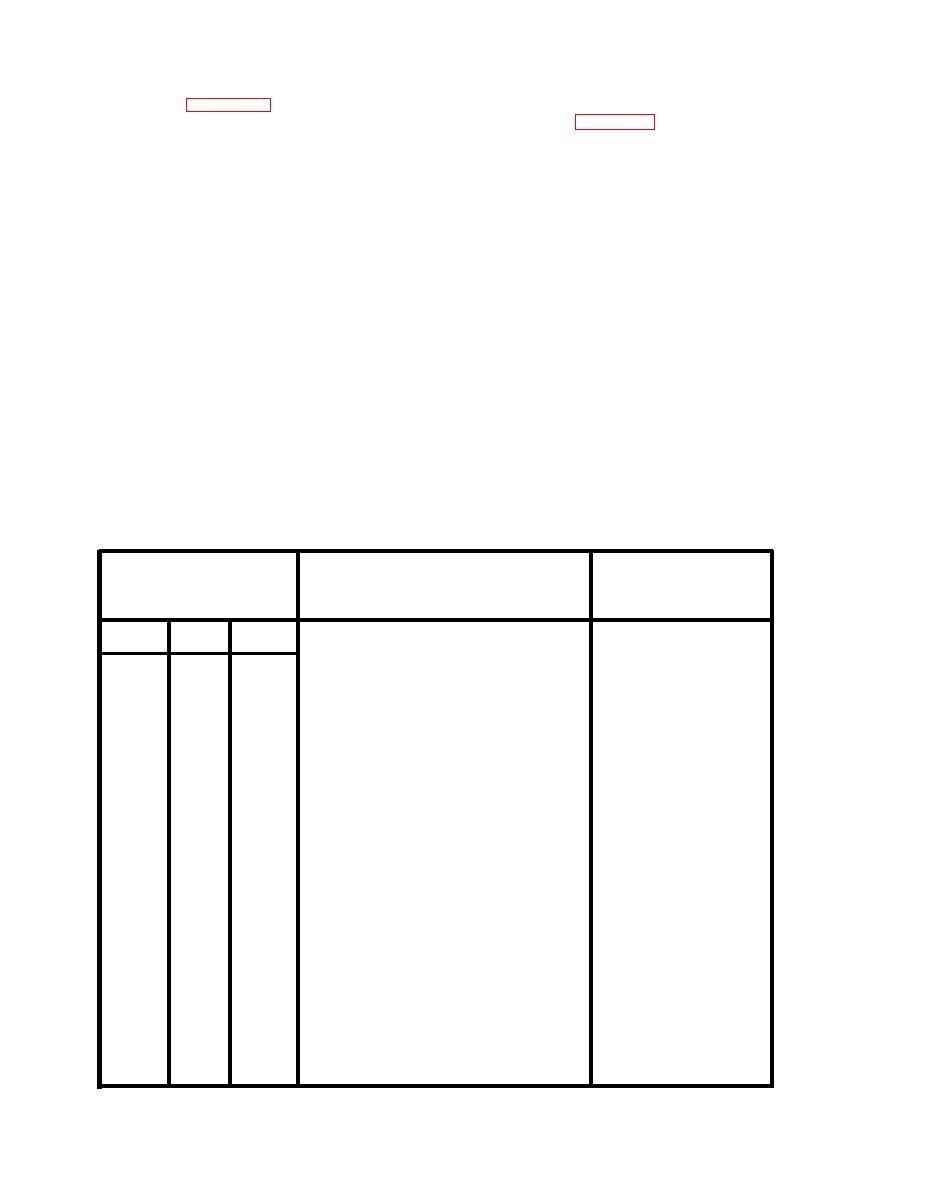

A - After Operation

D - During Operation

B - Before Operation

Time Required: 0.0

Time Required: 06

Work

ITEM(S) TO BE INSPECTED

Interval

Time

and

Sequence No.

Procedure

( M/H )

B

D

A

0.1

KNOBS, PUSHBUTTON SWITCHES,

6

1

TERMINALS, CONNECTORS

Inspect for damage, security

or malfunction.

0.1

DISPLAY AND ANNUNCIATORS

7

Inspect for damage or mal-

function.

0.1

2

TERMINALS AND CONNECTORS

Secure or replace any items

not securely installed or broken.

0.1

FUSE

3

8

Inspect and replace defective

fuse.

0.1

4

POWER CABLE

Inspect and replace cracked,

frayed or burned cable.

0.1

TEST LEADS

9

5

Inspect and replace or repair

defective test leads.