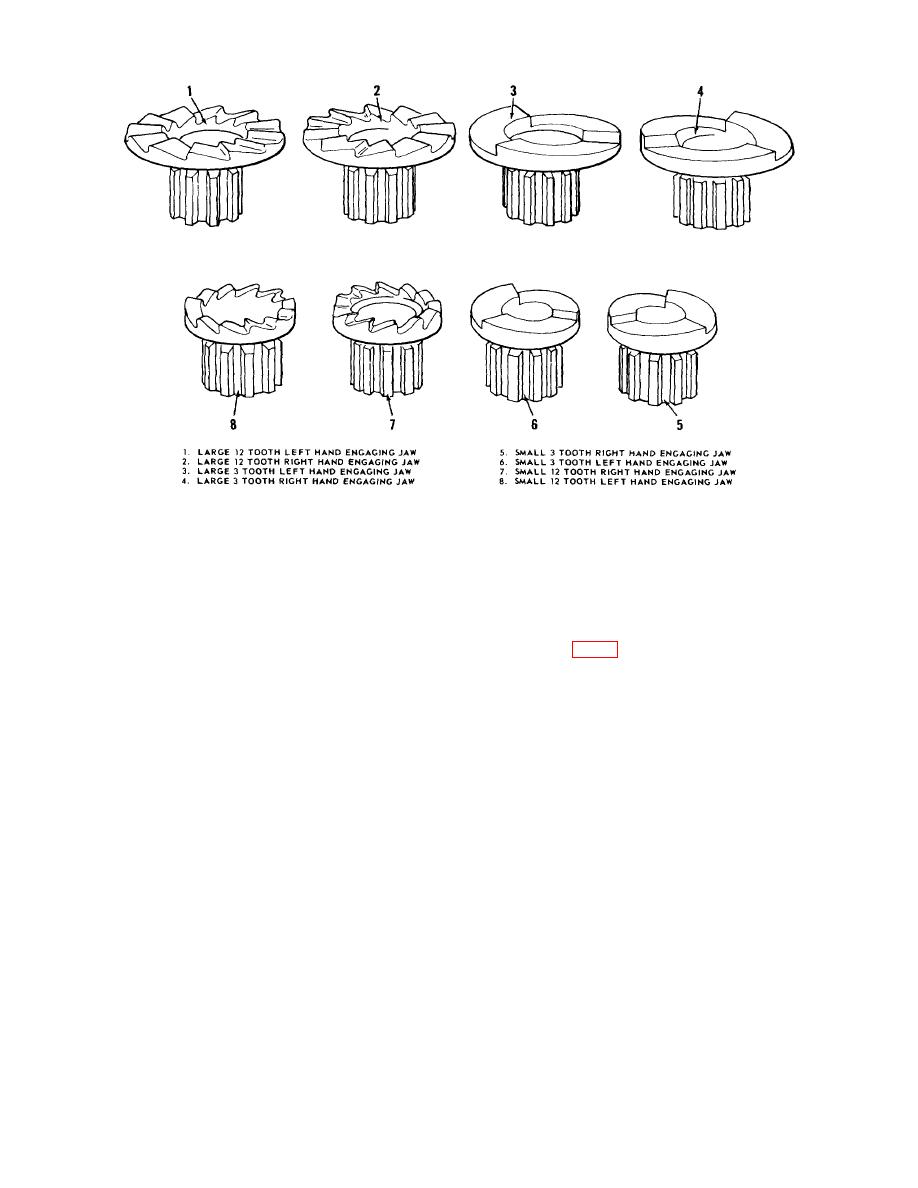

Figure 9. Starter Engaging Jaws

clockwise. This will prevent over-speeding of starter

being tested.

19. STOPPING OPERATIONS

c. Switch external power source on.

This

energizes starter, causing starter jaw to engage jaw of

Stopping operations consist of switching

starter torque tester.

external power source off and releasing brake pressure

by turning control cap located on brake pressure control

assembly (4, fig. 2) counterclockwise.

away rpm designated in applicable technical manual for

starter being tested. Make sure starter breaks away

from starter torque tester when tachometer (10) reads

20. EQUIPMENT HANDLING

designated rpm.

e. Increase current applied to starter until

a. Exercise extreme care in unpacking and

tachometer reaches rpm designated in applicable

handling instruments and other accessories of starter

technical manual for starter being tested to perform

torque tester.

slippage test. Apply braking pressure by turning control

b. If an instrument is dropped, thoroughly check

cap located on brake pressure control assembly (4) and

and test before use.

note that starter begins to slip when torquemeter (11)

reads specified braking pressure for starter being tested.

Caution: The tachometer will be

f. Increase voltage to starter by means of variable

damaged if the gear reduction unit is

resistor and decrease braking pressure by turning

not used when testing starters or

control cap on brake pressure control assembly (4)

actuators with output shaft speeds

counterclockwise. This check is to make sure starter

over 150 rpm.

torque tester will reach specified rpm and current output

designated in applicable technical manual for starter

being tested.

9