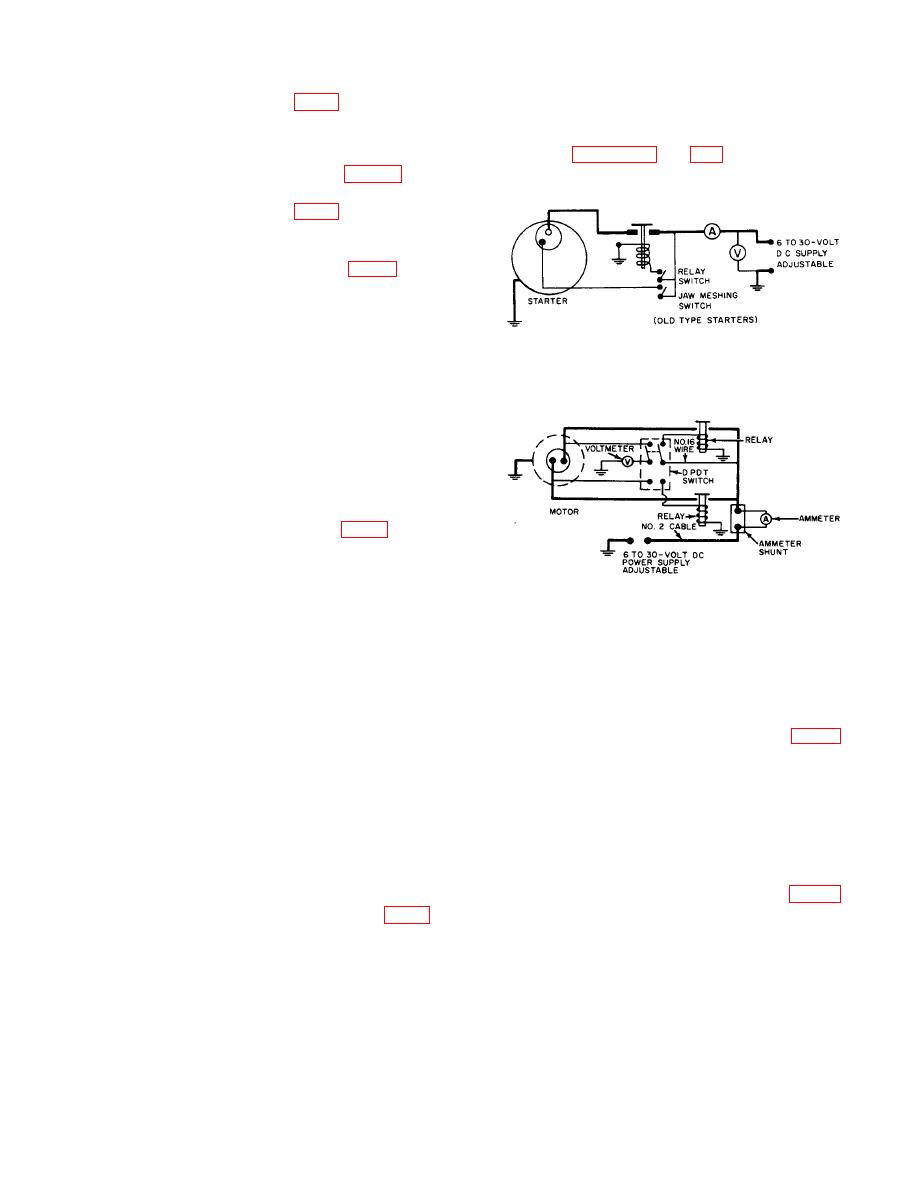

Note: Testing actuators or retraction

(3) Install cotter pins (14, fig. 5) through each

motors requires a different wiring

end of upper pivot pin (15).

setup from that shown for starters.

(4) Install lower pivot pin (16) through base

and frame assembly (31) and through

difference in wiring setup.

mounting support (3, fig.

4) of

torquemeter.

(5) Install cotter pins (14, fig. 5) through each

end of lower pivot pin (16).

be installed on either side of the test stand by

interchanging the flexible drive shaft.

12. INSTALLATION OF STARTER TORQUE TESTER

Figure 6. Typical Wiring Diagram for Testing

Install the starter torque tester as follows:

Starters

a. Mount starter torque tester on a heavy bench or

other firm structure using four mounting bolts.

b. Mount tachometer to bench or a suitable stand

to prevent damage during operation of tester.

c. Connect power source wires to an external

adjustable dc power supply, varying from 6 to 30 volts

and capable of supplying 300 amperes continuously.

d. Connect flexible drive shaft (18, fig. 5) from

tachometer to starter torque tester at tachometer drive

assembly (19).

e. Ground starter torque tester to negative side of

external power source.

Figure 7. Typical Wiring Diagram for Testing

Actuators

Section II. CONTROLS AND INSTRUMENTS

13. GENERAL

15. OPERATOR'S INSTRUMENTS

This section describes, locates, illustrates, and

furnishes the operator or crew sufficient information

attached between either the right or left carrying arm (1)

pertaining to the controls provided for the proper

of the starter torque tester and the base and frame

operation of the starter torque tester.

Careless

assembly (9). The location depends on whether the

operation or improper setting of the controls will cause

starter being tested has left-hand or right-hand rotation.

damage to the equipment. For this reason, it is

The torquemeter measures the torque of the starter in

important to know the function of every control.

foot-pounds.

Three torquemeter assemblies with

different ranges are provided for testing starters,

actuators, or retraction motors.

14. OPERATOR'S CONTROLS

mounted to the bench or a suitable stand.

The

The brake pressure control assembly (4, fig. 2)

tachometer indicates the rotational speed of the starter

is located top center on the starter torque tester. Brake

jaw in either clockwise or counterclockwise direction.

pressure is applied by turning the control cap on the

The tachometer can be connected directly on the starter

brake pressure control assembly. Turning the cap

torque tester for speeds up to 150 rpm; for higher

clockwise will apply pressure to the brake; turning the

speeds, however, the tachometer reduction drive

cap counterclockwise will release the brake.

assembly (3) supplied with the starter torque tester must

be used.

7