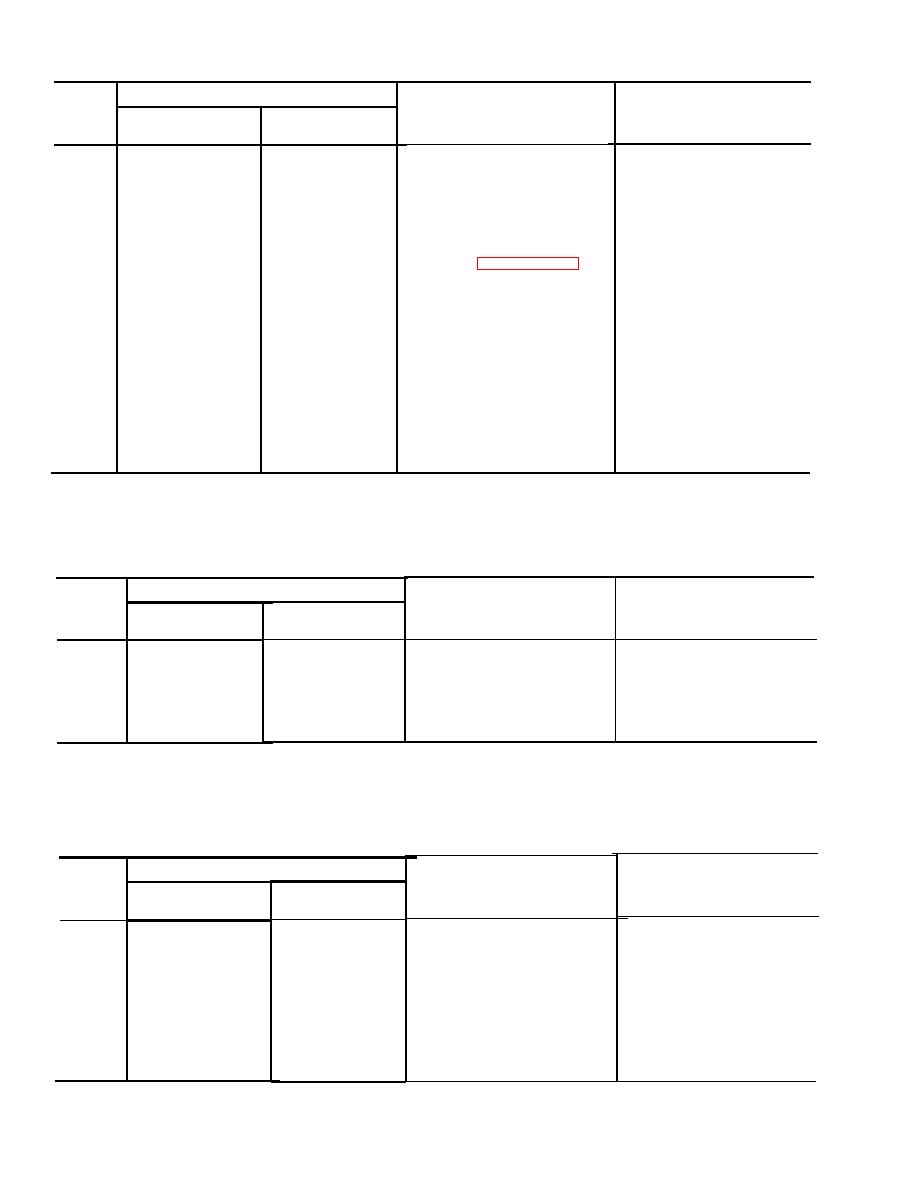

TM 11-6625-539-14-4

Control settings

Step

Performance standard

Test Procedures

Equipment

No.

Test

under test

equipment

1

N/A

Controls may be set

a. Inspect all parts for loose

a. All screws and nuts must be

in any position.

mounting and missing screws

tight with none missing.

and nuts.

b. Meter must he in good condi-

b. Inspect meter for binding of

movement, damaged glass,

tion with legible dial and free

and illegible dial.

movement.

c. Check to see that all parts

c. All items comprising operable

listed in paragraph 1-11 are

equipment must be present,

present.

2

N/A

Set controls as indi-

a. Rotary switches rotate with-

a. Check operation of all rotary

cated.

switches, rotating them to all

out catching, lock positively

positions.

in each position, and operate

through the full operating

range.

b. Toggle switches operate

b. Operate toggle switches to

down position and release.

smoothly and return to up

position when toggles are re-

leased.

c. Knobs rotate freely through

C.

Operate variable resistor con.

full operating range without

trols in full operating ranges.

catching or binding.

--

b. Test Connections and Conditions. Cover re-

moved from case of test set.

c. Procedure.

a. Test Equipment and Materials, None.

Control settings

Step

Performance standard

Text production

Equipment

No.

Test

under test

equipment

Pointer deflects to BAT CHK

1

N/A

Press and hold BAT

Check deflection of meter

position.

CHK switch to

pointer.

down position. Re-

maining controls

may be set to any

position.

7-16. Stability Test

b. Test Connections and Conditions. As indi-

cated below.

a. Test Equipment and Materials. Any good PNP

c. Procedure.

or NPN transistor.

Control settings

Sep

Performance standard

Test procedures

Equipment

Test

No.

under test

equipment

Meter must deflect.

Insert transistor into test

POLARITY switch:

1

N/A

socket on panel.

PNP or NPN as

applicable.

FUNCTION switch:

BETA.

a. Record deflection indicated

a. Meter indicates on-scale de-

RANGE switch: ad-

2

on beta scale.

flection.

just to provide on-

b. Allow condition to remain for

b. Beta indication must not

scale needle deflec-

full minute.

drift more than 3 percent of

tion.

full-scale deflection.

7-10