TM 11-6625-444-14-1

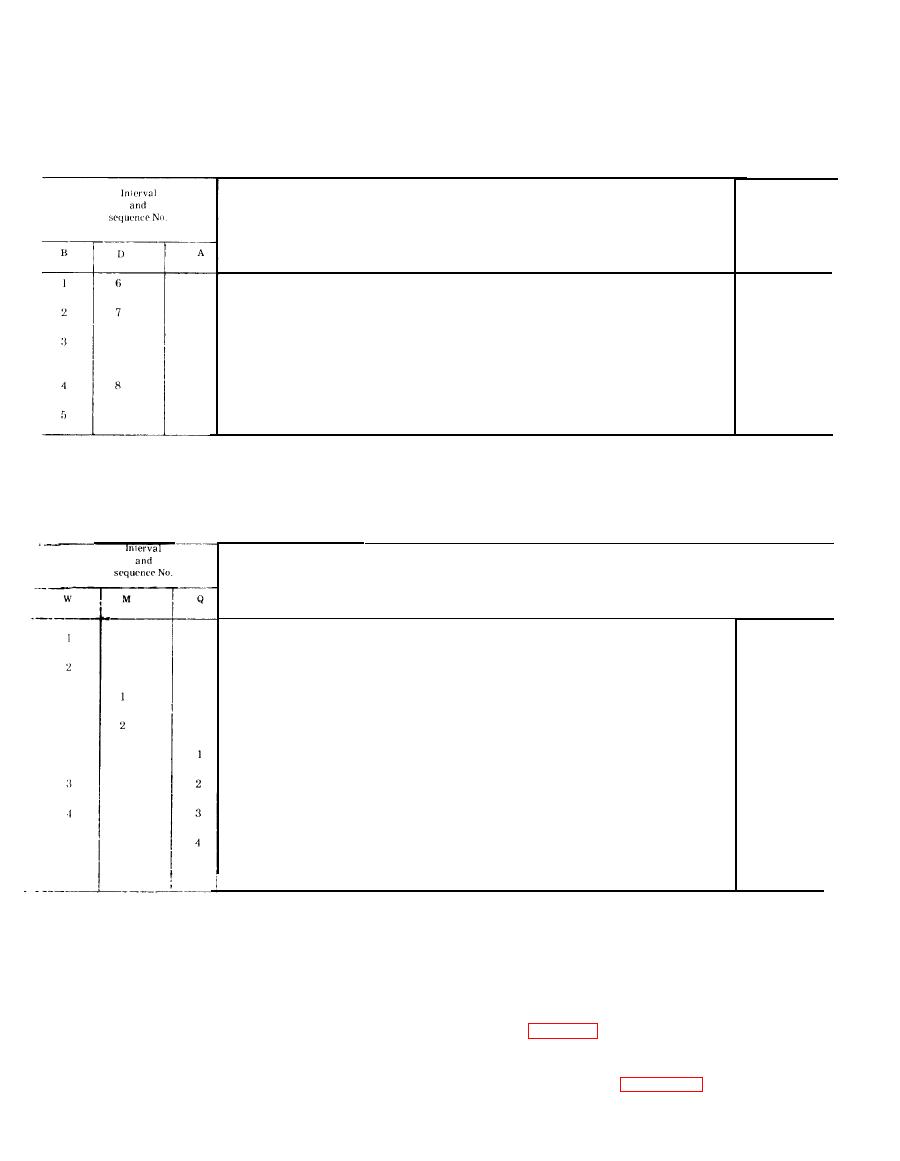

A - After Operation

D. During Operation

Time required: 0.0

Work

lime

Item to be inspected

(M H)

procedure

KNOBS, PUSHBUTTON SWITCHES, FUSE, INPUrr-OUTPUT TERMINALS

0.1

Inspect for damage, security or malfunction.

READOUT TUBES AND INDICATORS (ANNUNCIATOR)

0.1

Inspect for damage and malfunction.

INPUT/OUTPUT TERMINALS

0.1

Secure or replace as necessary any items not securely installed or broken items.

FUSE

Inspect and replace defective fuse.

0.1

POWER CABLE

Inspect and replace cracked, frayed or burned cable.

0.1

Total man-hours required: 0.9

Work

Item to be inspected

time

procedure

(M/H)

KNOBS, PUSHBUTTON SWITCHES FUSE, INPUT/OUTPUT TERMINALS

0.1

Inspect for damage, security or malfunction.

READOUT TUBES AND INDICATORS (ANNUNCIATOR)

0.1

Inspect for damage and malfunction.

COVERS

0.1

Repair or replace as necessary any visibiy damaged covers.

CHASSIS SURFACES

0.2

Clean.

KNOBS

0.1

Secure or replace as necessary any items not securely installed or broken items.

INPUT/OUTPUT TERMINALS

0.1

Secure or replace as necessary any items not securely installed or broken items.

POWER CABLE

0.1

Inspect and replace cracked, frayed, or burned cables.

CHASSIS FEET

0.1

Inspect and replace cracked or broken feet.

Section Ill. TROUBLESHOOTING

4-5. General

4-6. Procedure

This section contains troubleshooting in-

When the voltmeter fails to operate correctly,

structions for the voltmeter. Any malfunction that

turn it off and check the following items:

scope

of the

operator,

a. Wrong control settings or improper input

is

beyond

the

organizational, or direct support maintenance

connections (para 3-3, 3-8, and 3-9).

activities to correct shall be referred to general

b. Damaged or incorrectly connected power

support maintenance.

cord.