TM 11-6625-298-14

OPERATOR AND ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Section l. TOOLS AND EQUIPMENT

the operator and organizational technician are

4-1. General

listed in appendix C.

Tools and test equipment authorized for use by

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

deficiencies together with the corrective action

4-2. General

taken as prescribed in TM 38-750.

To be sure that the ZM-21(*)/U is always ready

for operation, it must be inspected systematically

so that defects may be discovered and corrected

Periods

before they result in serious damage or failure. The

Preventive maintenance checks and services of the

necessary preventive maintenance checks and

ZM-21(*)/U are required daily, weekly, monthly,

services to be performed are listed and described in

and quarterly. In addition, the weekly preventive

maintenance checks and services must be per-

sequence of minimum inspection requirements.

formed under the following conditions:

Defects discovered during operation of the unit will

a. Upon initial receipt.

be noted for future correction to be made as soon

b. Upon return from higher category main-

as operation has ceased. Stop operation im-

tenance.

mediately if a deficiency is noted during operation

which would damage the equipment. Record all

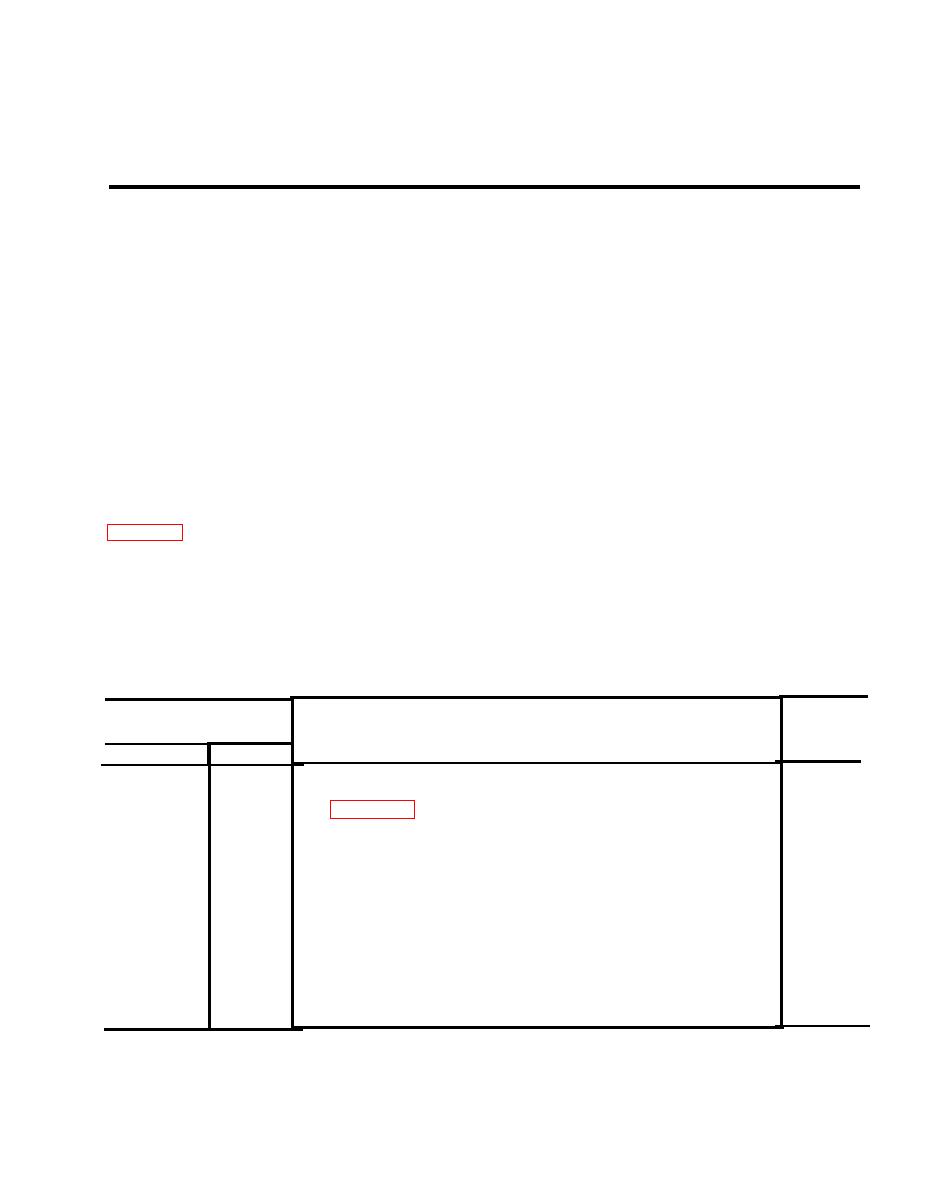

w- Weekly

DDaily

Time required: 0.4

Time required: 0.2

ITEM TO BE INSPECTED

Interval

Worktime

and

(T/ H)

sequence No.

PROCEDURE

W

D

0.1

1

1

Check to see that the ZM-21(*)/U is complete against the component listing

0.1

2

EXTERIOR SURFACES

Check to see that exterior is clean and free from dust, dirt, fungus, rust, and

corrosion.

0.1

3

HARDWARE

Check to be sure that all screws and handles are securely fastened.

4

TEST LEADS

Check for loose clips and terminals, cleanliness of terminals, and breaks in

the insulation.

0.1

5

OPERATION

2

While the ZM-21(*)/U is in operation, be alert for symptoms of trouble.