TM 55-4920-231-14

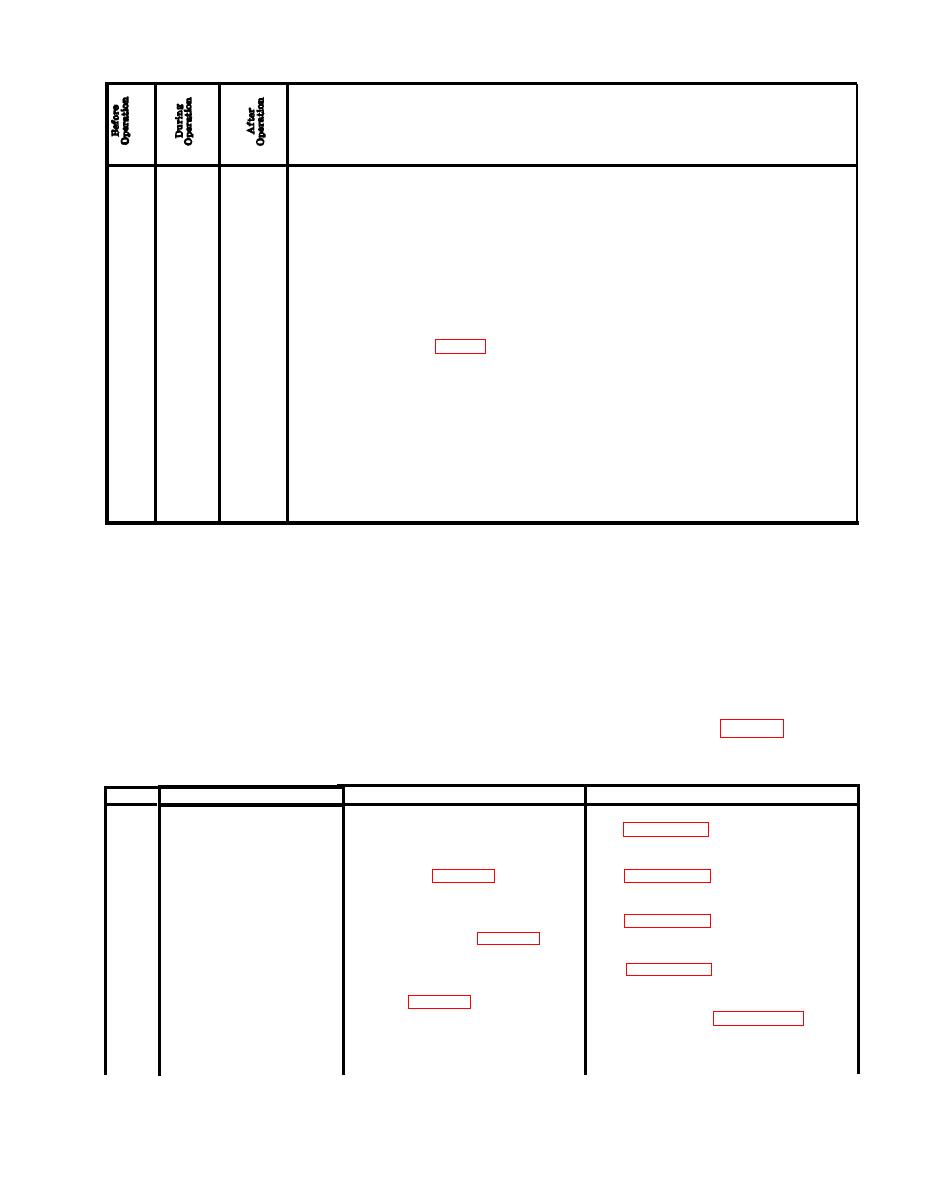

Table 4. Operator's Daily Services (Cont)

Producdure

X

X

X

Oil sumps. Check vacuum and pressure sumps for pressure of oil. Clean sump and

filter when there is oil present

x

Valves. Check all valves for proper operation. They must turn freely but not be too

loose.

x

Work area. Place testar on a firm and level stand in a clean, well-lighted area at a

height at which the instruments are easily visible and the controls readily accessible.

x

Power source. Provide a power source compatible with the requircmens of the tester

and make certain all connections are secure.

x

publications. Provide a serviceable copy of this manual, TM 50-4920-231-14, and the

current lubrication order for the equipment.

x

Accessories. Check table 1 to see that all accessories are with equipment or accounted

for.

x

Case leak test. Perform master instrument case leak test to determine if there is leak-

age in tester instrument.

x

Unusual operation. Check for unusual noises, excessive vibration, evidence of over-

heating, and lack of pressure or vacuum. Stop teeter immediately when an unusus

condition exists and do not resume operation until it is determined that no further

damage will result, or the defect is repaired.

x

Stopping. Remove all foreign material and clean tester and accessories thoroughly.

Account for all accessories and stow them neatly and compactly in cover compart-

ment.

Section IV. TROUBLESHOOTING

The possible remedy recommended is described

55. GENERAL.

opposite the probable cause.

This section provides information useful in

56. TROUBLESHOOTING.

diagnosing and correcting unsatisfactiry opera-

A tabulation of symptoms of probable troubles

tion or failure of the tester, or any of its com-

and remedies which are likely to be encountered

ponents Each trouble symptom stated is fol-

before, during, or after operation, and repair of

the equipment are contained in table 5.

lowed by a list of probable cause of the trouble.

Table 5. Troubleshooting

Possible remedy

Probable cause

Trouble

Item No.

Provide a power source

No power source.

Indicator light does not

(paragraph 35),

illuminate and motor does

Tighten connection.

Loose connection on power cable.

not run when power

Repair or replace cable

Defective power cable (check

switch is in ON

continuity, figure 10).

position.

AC OPERATION ONLY

Repair or replace wiring harness

Defective lead or connection be-

tween connector and capacitor

(check continuity, figure 10).

Repair or replace wiring harness

Defective lead or connection be-

tween capacitor and rectifier.

(Check for continuity and

shorts, figure 10.)

Replace rectifier (paragraph 80).

Open rectifier or shorted

capacitor and motor.

Replace capacitor.

(Check voltage on yellow coded

lugs of rectifier. If voltage