TM 55-492-231-14

SUPPRESSION.

a. Place a radio receiver that is in good oper-

ating condition in a position not more than 5

feet from the tester. A wide band receiver with

a frequency range of 0.15 in 1000.0 megacycles

is preferred.

b. Start the tester and tune the receiver in to

three widely separated frequencies at maximum

volume. Use frequencies that are free of signals

with strong carriers so that the receiver will be

in its most sensitive operating condition.

c. When the tester is operating, listen to the

receiver for interference which ceases when the

tester is stopped and which indicates that the

suppression is defective.

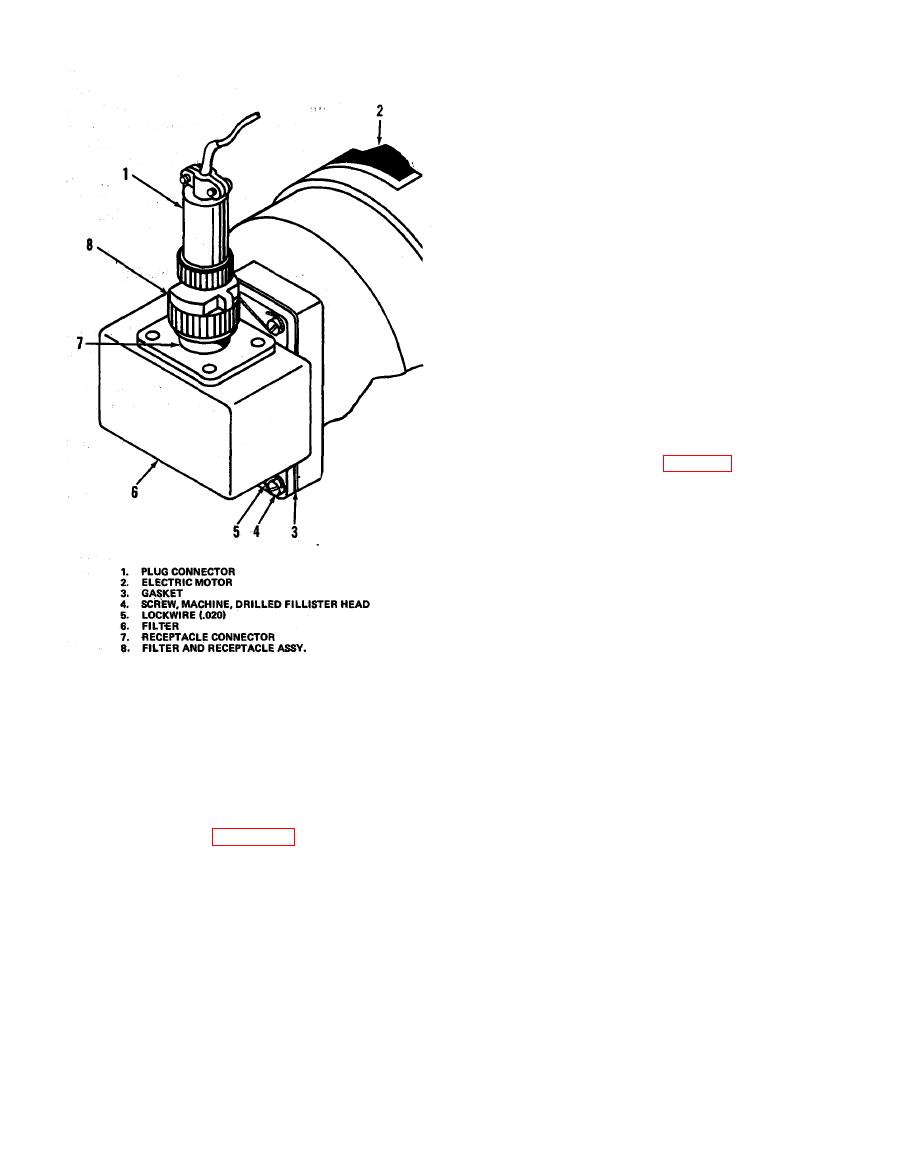

60. REPLACEMENT OF SUPPRESSION

COMPONENT.

a. Removal.

(1) Disconnect plug (1, figure 19) from re-

ceptacle (7).

(2) Cut lockwire (5) and remove from

Screws (4).

(3) Remove screws (4) securing filter (6)

to electric motor (2) and remove filter and gas-

ket (3) from motor.

b. Installation.

(1) Place gasket (3) and filter (6) in posi-

tion on motor (2) and secure with screws (4).

(2) Secure the top two screws (4) together

and the bottom two screws (4) together with

AV 001480

the lockwire (5).

(3) Install the plug (1) on the receptacle

(7).

Section VI. PNEUMATIC SYSTEM

from the sump flows through two pressure con-

61. GENERAL.

trol valves (16 and 17). The pressure IN-

The pump (19, figure 11) serves the dual

CREASE valve (17) controls the amount of air

function of developing pressure as well as vac-

permitted in the system and the pressure DE-

uum for operation of the tester. In the pressure

CREASE valve (16) opens the line to the ambi-

section a mixer of air and oil is pumped into

ent air, allowing system pressure to bleed off.

the reservoir (33) where the oil and air are

The available pressure level, as fixed by the con-

separated. The separated oil drops to the bottom

trol valves is sent to the pressure relief valve

of the reservoir where it is fed to the pump for

(14) and PRESSURE selector valve (31). Setting

lubrication purposes, the air being forced out at

the PRESSURE selector valve at the desired test

the top of the reservoir under pressure, The

position completes the circuit to the instrument

pressurized air, after going through the check

under test and simultaneously connects the in-

valve (32) whose function it is to prevent oil

strument under test and the master instrument

from entering instrument lines during operation,

to one of the pressure relief valves (12 or 13).

enters an oil sump (15) and passes through a

filter which is an integral part of tire sump. Air

The pressure relief valve (14) is in the line at