TM 11-6625-539-14-3

GENERAL SUPPORT TESTING PROCEDURES

b. Preliminary Instructions. Follow the in-

s. Testing Procedures. The testing procedures

structions preceding each chart before proceed-

are prepared for use by Electronic Field Mainte-

ing to the chart. Perform each step in sequence,

nance Shops and Electronic Service Organiza-

Do not vary the sequence. For each step, per-

tions responsible for general support mainte-

f o r m all the actions required in the C o n t r o l

nance of electronic equipment to determine the

settings column; then perform each specific test

acceptability of repaired equipment. These pro-

p r o c e d u r e , and verify it against its perform-

cedures set forth specific requirements that re-

ante standard.

paired equipment must meet before it is returned

to the using organization.

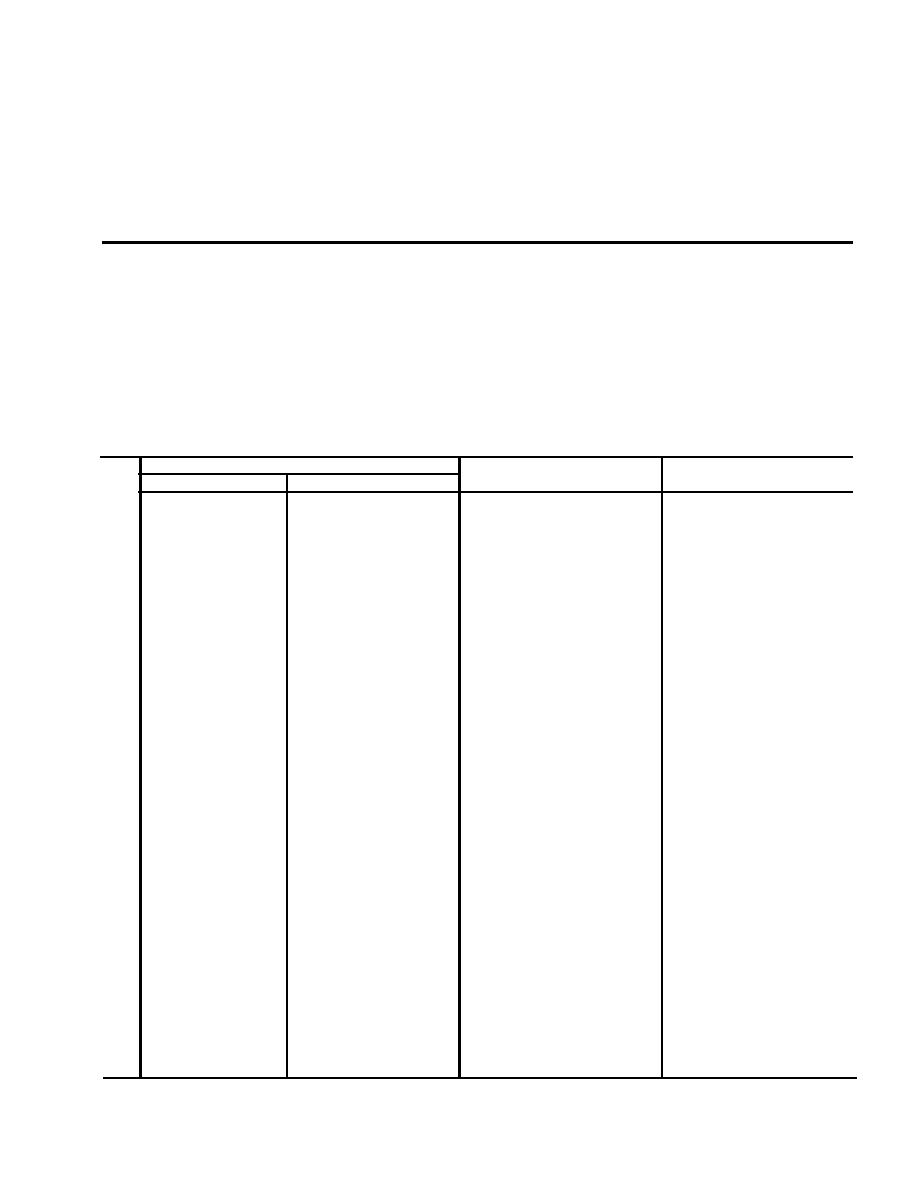

c. procedure.

Control settings

Step

Performance standard

Equipment under test

Test procedure

Test equipment

No.

a. Inspect case and chassis

1

e Controls may be in any

U. No damage evident or

N

o

n

for damage, missing

position.

parts missing. External

parts, and defective

surfaces intended to be

painted do not show bare

condition of paint.

metal.

Note. Touchup painting is recoin.

mended in place of refinishing

whenever practical : screw heads:

binding posts, receptacles, and

other plated partai will not be

painted or polished with abras-

ives.

b. Inspect all controls and

b. Screws, bolts, and nuts will

mechanical assemblies

be tight with none miss-

for loose or missing

ing.

screws, bolts, and nuts.

c. No loose parts or damage.

c. Inspect all connectors, soc-

kets, receptacles, and

No missing parts.

fuseholders and meter

for looseness, damage,

or missing parts.

2

None . . . . . . . . . . . . .

Controls may be in any

a. Rotate all panel controls

a. Controls rotate freely with-

position.

throughout their limits

out binding or excesive

of travel.

looseness.

b. Inspect dial stops for

b. Stops operate properly

damage or bending;

without evidence of dam-

check for proper oper-

age.

ation.

c. Operate all switches

c. Switches operate properly.

MX-1292/PAQ

3

Connect mercury

Controls may be in any

Turn on mercury vapor lamp

All repaired or disturbed

vapor lamp.

position.

and expose portion of

electrical components and

equipment that has been

chassis surfaces are cov-

repaired or disturbed to

ered. There must be no var-

direct rays of lamp.

nish on switch contacts or

moving parts of mechanical

assemblies.

Note. Moisture fungiproofing var-

nish glows gray-green under rays of

mercury vapor lamp.