TM 11-6625-2981-14

SCHEDULED

MAINTENANCE

4 - 2 . Scheduled Maintenance.

Introduction.

This chapter describes the scheduled and preventive

Ohmmeter should be cleaned, lubricated and per-

maintenance for the ohmmeter.

formance tested at 6 month intervals.

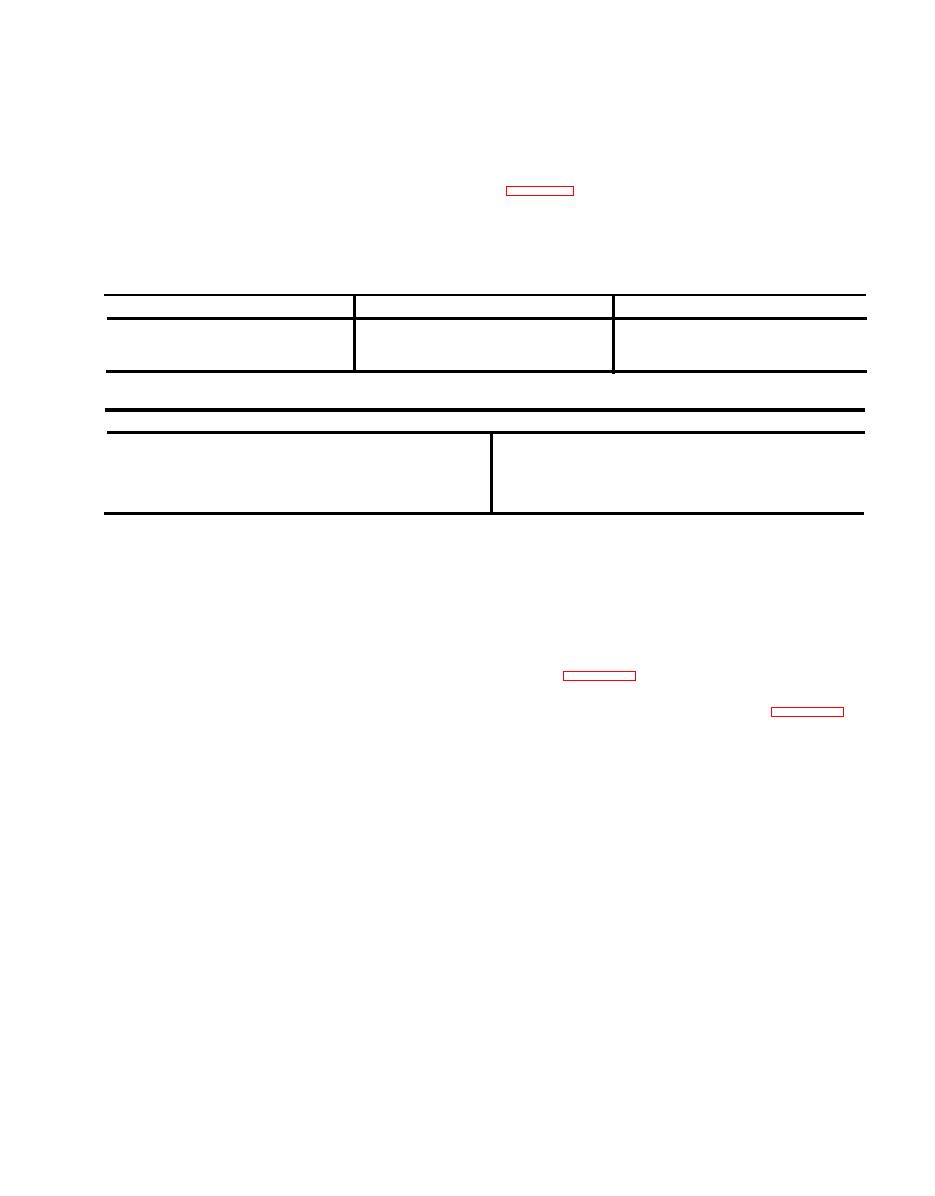

Periodicity

Maintenance Action

Reference

Cleaning

S

4-3

S

Lubrication

4-4

S

Performance Test

4-5

Nomenclature

National Stock Number

Tool kit, electronic eqpt. TK-101/G

I

Resistor, fxd film 1 Megohm 1%

Resistor, fxd film 10 Megohm 1%

Resistor, fxd film 100 Megohm 1%

Voltmeter, electronic ME-202C/U

4-3. Cleaning.

air source must limit the nozzle pressure to

no more than 29 pounds per square inch

CAUTION

guage (PSIG). Goggles must be worn at all

If solvents are required for cleaning, use

times while cleaning with compressed air.

only alcohol or freon. Do not use tri-

b. Interior Cleaning. Remove the six screws holding

chlorotrifluoroethane (trichloroethane) as

the ohmmeter to the case. Remove the ohmmeter from

that solvent will damage some of the plastic

the case. Using compressed air, clean out the case.

parts. Do not use abrasives or scouring

Refer to figure 4-1. Clean ohmmeter if dirt is present.

powders as they will damage the finish and

Use compressed air for cleaning. Do not blow air di-

may leave a residue.

rectly into meter movement, item 1 of figure 4-1. Do

a. Exterior Cleaning. Clean the exterior surface of

not replace the ohmmeter in the case until lubrication,

all dirt or grease using a clean cloth.

4-4, has been completed.

WARNING

To be usable for cleaning, the compressed