TM 9-4935-282-34

803D

(3) Being careful to avoid wiring damage, gently lift

front panel assembly from instrument and set face down in

SPECI-

from of instrument.

RECOMMENDED

FICATIONS

(4) Remove screws holding range resistor board to

EQUIPMENT

REQUIRED

front panel assembly.

(5) Push printed circuit board aside enough to

DC CALIBRATION:

allow access to light holders.

(6) Remove light holder from bracket by applying

Fluke 301C or 301E Power Supply

pressure to each side of holder.

(7) Remove cardboard light shield and replace

Saturated standard cell bank with an

The equipment used

lamp.

accuracy of +0.001%

must provide 500,

(8) On rack models , remove screws holding cover

50, 5, and 0.5 volts

to instrument and set cover aside.

Voltage reference divider having

with an accuracy

(9) Remove light holder from bracket by applying

division ratios of 1, 10, 100, and 1000

of 0.005%.

pressure to each side of holder.

with an accuracy of 0.001%

(10) Remove cardboard light shield and replace

lamp.

Galvanometer suitable for use

with above voltage reference

4-4. CALIBRATION

divider

a. GENERAL. The calibration procedure is divided into

AC CALIBRATION:

two main parts: DC differential voltmeter calibration (paragraph

Fluke Model 821A Differential

The equipment used

The 803D may be calibrated as often as deemed necessary.

must provide 500,

However, it is recommended that DC differential voltmeter

50, 5, and 0.5 volts

calibration be done every 3 months. The AC to DC converter

calibration should be done every month.

For special

Fluke 301C or 301E Power Supply

AC at 400 cycles,

applications where extreme accuracy is required, it may be

10 kilocycles, and

desired to calibrate the instrument more often. Calibration

20 kilocycles with

should be accomplished in a draft-free area with an ambient

Krohn-Hite LDS-1500 oscillator

an accuracy of at

temperature of 72(+3)F for maximum accuracy under

least 0.03% and with

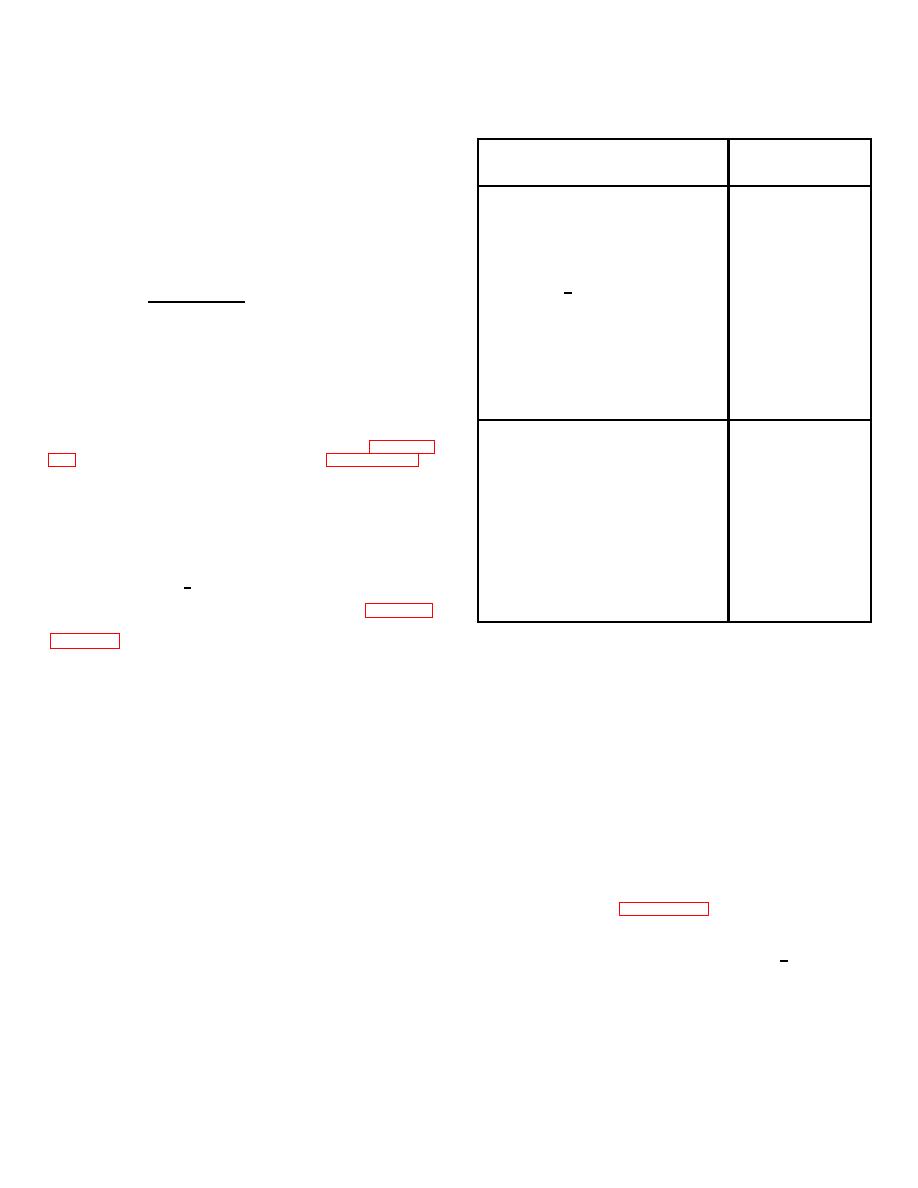

laboratory conditions. The recommended equipment and the

Fluke 540A Transfer Standard

less than 0.1% total

specifications required for calibration are shown in figure 4-3.

harmonic distortion.

All controls on the cabinet model may be located with the aid of

Figure 4-3. CALIBRATION EQUIPMENT

The ventilation holes on the cabinet model provide an easy

means of reaching R121, R222, and R232. An insulted

(d) Set up necessary equipment to provide

screwdriver must be used when adjusting these controls to

DC voltages of 500, 50, 5, and 0.5 volts DC with an accuracy

prevent shorting the control to chassis ground. To reach the

of 0.005%. Proceed as follows: turn on all test equipment and

calibration controls at the front of cabinet models, the

allow it to warm to equilibrium temperature (about 1/2 hour);

instrument must be slid partly out of its cabinet. On rack

set proper standard cell voltage on divider; apply 500 volts DC

models, all controls may be easily reached through labeled

into divider from power supply; set divider to 500 and zero

access holes.

galvanometer by varying output of power supply; voltages of

b. DC DIFFERENTIAL VOLTMETER CALIBRATION.

500, 50, 5, and 0.5 volts DC are made available at output posts

For convenience, the DC differential voltmeter calibration is

by merely changing position of voltage selector switch on

divided into four parts: preliminary calibration, null detector

voltage divider.

calibration, reference supply calibration, and range divider

(e) Connect chassis ground binding post to

calibration. Normally, all four parts are performed in the

line ground.

sequence given here. However, the calibration procedure is

written so that any part may be calibrated by performing the

(2)

Null Dete ctor Calibration.

procedure for just that part.

(a) Perform

preliminary

calibration

(1) Preliminary Calibration Procedure.

procedure as stated in paragraph 4-4b (1).

(a) Set 803D meter to zero with mechanical

(b) Adjust null detector ZERO ADJ control

adjustment screw on front of meter case.

R232 until meter indicates zero.

(b) Set switches on 803D as follows:

(c) Apply 500 volts DC (+0.005%) to

RANGE

500

NULL

VTVM

AC - DC polarity

+ (positive)

(d) Adjust VTVM GAIN ADJ control R222

all voltage read-

0 (zero)

for full scale deflection.

out dials

(c) Set power switch to ON and allow 803D

to warm to equilibrium temperature (about 1 hour) inside its

case. Meanwhile, proceed with step (d).

4-5