TM 9-4935-282-34

803D

(3)

500 VDC Reference Supply Calibration.

c. AC TO DC CONVERTER CALIBRATION. The DC

(a) Perform

preliminary

calibration

Differential Voltmeter section of the 803D must be within

procedure as stated in paragraph 4-4b (1).

specifications before the AC to DC Converter can be

(b) Center CALIBRATE control at its center

accurately calibrated. The AC to DC Converter must be

of rotation.

calibrated in the following order.

(c) Set NULL switch to 10 and voltage

readout dials to 499.9 10.

(1)

Preliminary Calibration Procedure.

(d) Apply 500 volts DC (+0.005%) to

(a) Zero instrument as stated in paragraph

voltmeter.

(e) Adjust 500V ADJ control R121 for a null.

(b)

Set switches on 803D as follows:

(f) Set NULL switch to 0.1 volt.

RANGE

500

(g) Null meter by adjusting CALIBRATE

NULL

0.01

control.

AC - DC polarity

AC

(h) Advance OPERATE-CALIBRATE switch

voltage readout

499.9 10

against spring tension to CALIBRATE and null meter by

dials

adjusting REF CAL ADJ control R318.

(c) Check for excessive converter output

noise as follows: set RANGE switch to 0.5, NULL switch to

(4)

Range Divider Calibration.

0.01, AC - DC polarity switch to AC, and all voltage readout

(a) Perform

preliminary

calibration

dials to 0 (zero); short input terminals of 803D; if the meter

procedure as stated in paragraph 4-4b (1).

needle is not within 150 microvolts (7-1/2 small divisions) of

(b) Set switches on 803D as follows:

null, converter noise is excessive and the trouble must be

RANGE

50

corrected before proceeding with calibration; if trouble occurs it

NULL

0.01

is usually the result of the input tube (V501), the filament

voltage read-

49.9910

supply, or the 500 volt supply being noisy; remove short from

out dials

input terminals.

(c) Apply 50 volts DC (+0.005%) to

(d) Allow 803D to warm to equilibrium

voltmeter.

temperature inside its case (about 1 hour). Meanwhile,

(d) Null 803D meter by adjusting 50V DC

proceed with step (e).

ADJ control R323.

(e) Set up the necessary equipment to

(e) Set RANGE switch to 5 volts.

provide 500, 50, 5, and 0.5 volts AC with an accuracy of at

(f) Apply 5 volts DC (+0.005%) to

least 0.03% at frequencies of 400 cycles, 10 kilocycles, and

voltmeter.

20 kilocycles with less than 0.1 total harmonic distortion.

(g) Null 803D meter b adjusting 5V DC

y

Proceed as follows: connect equipment as shown in figure 4-5;

ADJ control R326.

turn on all test equipment and allow it to warmup to equilibrium

(h) Set RANGE switch to 0.5 volts.

temperature (about 1/2 hour; adjust DC power supply voltage

(i) Apply 0.5 volts DC (+0.005%) to

until differential voltmeter indicates rms value of AC voltage

voltmeter.

(j) Null 803D meter by adjusting 0.5V DC

ADJ control R329.

This completes the DC differential voltmeter calibration.

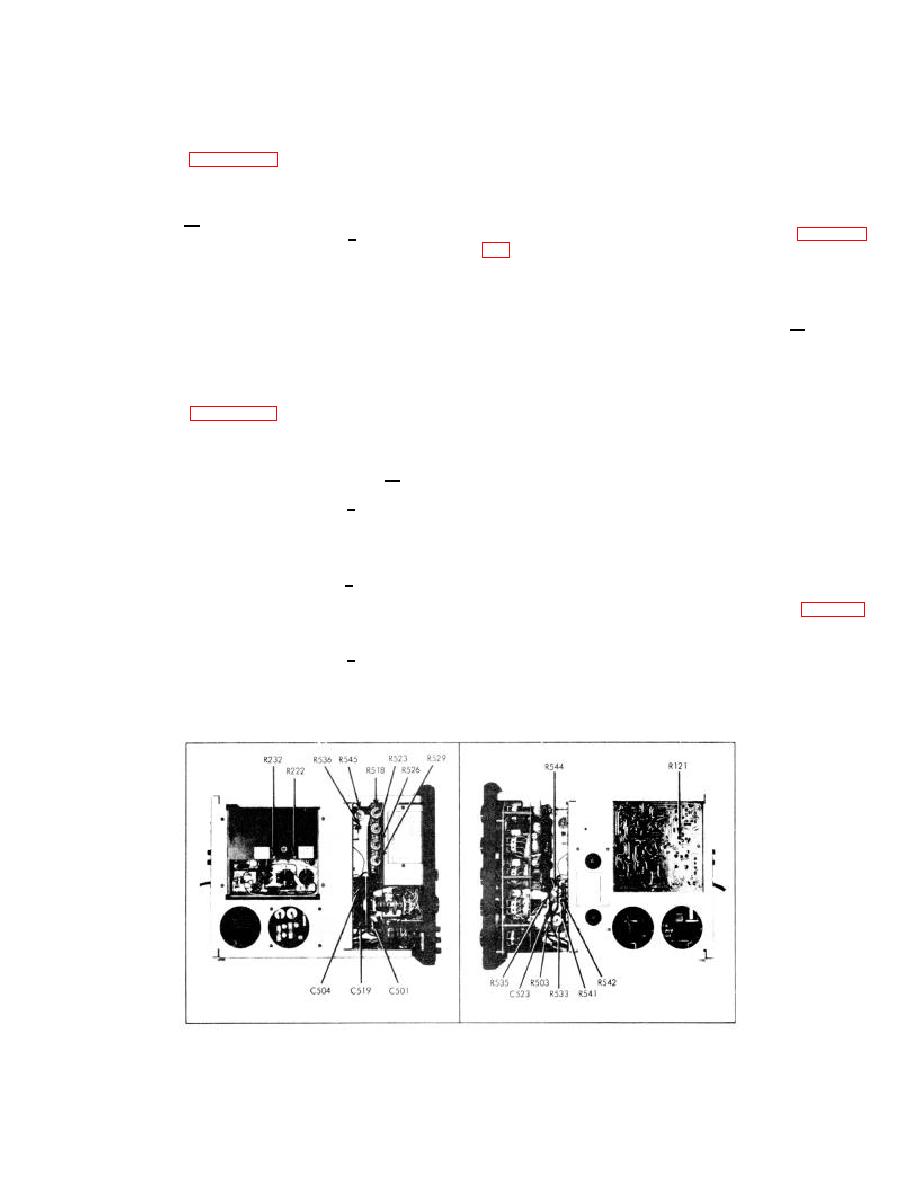

Figure 4-4. ADJUSTMENT LOCATIONS

4-6