TM 11-6625-2946-14/TM 08168A-14/1

CHAPTER

3

OPERATOR/ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

S e c t i o n 1. TOOLS AND EQUIPMENT

the operator and organizational maintenance of the test

3-1. Common Tools and Equipment

set.

Common tools and test equipment items required for

operator and organizational maintenance of the test set

3-3. Materials Required

are listed in the maintenance allocation chart, appendix

The following materials are required for operator/or-

D. Equivalent test equipment items may be substituted

ganizational maintenance

as necessary.

a. Lint-free cleaning cloth

b. Trichlorotrifluroethane

3-2. Special Tools and Equipment

c. Soft-bristled brush.

No special tools or test equipment items are required for

Section Il. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

(1) Preventive maintenance is the systematic inspec-

3-4.

General

tion, care, and servicing of the test set to insure its com-

To ensure that the test set is always ready for operation,

pleteness, serviceability, and immediate availability and

it must be inspected systematically so that defects maybe

capability for the testing of Radio Set AN/PRC-68.

discovered and corrected before they result in serious

(2) Since operation of the test set will be performed

damage or failure. The necessary preventive main-

by maintenance personnel at the organizational level,

tenance checks and services (PMCS) to be performed are

operator and organizational preventive maintenance

listed and described in table 3-1. The item numbers in-

checks and services are combined into a single procedure

dicate the sequence of the minimum inspection require-

(table 3-1 ).

ments. Defects discovered during operation of the unit

b. PMCS Scheduling. Preventive maintenance checks

will be noted for corrective action as soon as operation

for the test set are required on a before-operation, week-

has ceased. If a deficiency is noted that will result in

ly, monthly, and quarterly basis. In addition to these

damage to the equipment, stop operation immediately.

scheduled intervals, the before-operation and weekly

Record all deficiencies together with the corrective ac-

checks should be performed under the following special

tion taken as prescribed in TM 38-750. Marine Corps

conditions:

personnel will refer to current addition of TM

(1) Receipt of equipment.

4700-15/1.

(2) Return from higher category maintenance.

(3) Monthly, if the equipment is maintained in

3-5. Scope of Operator/Organizational

standby condition.

Preventive Maintenance

a. General.

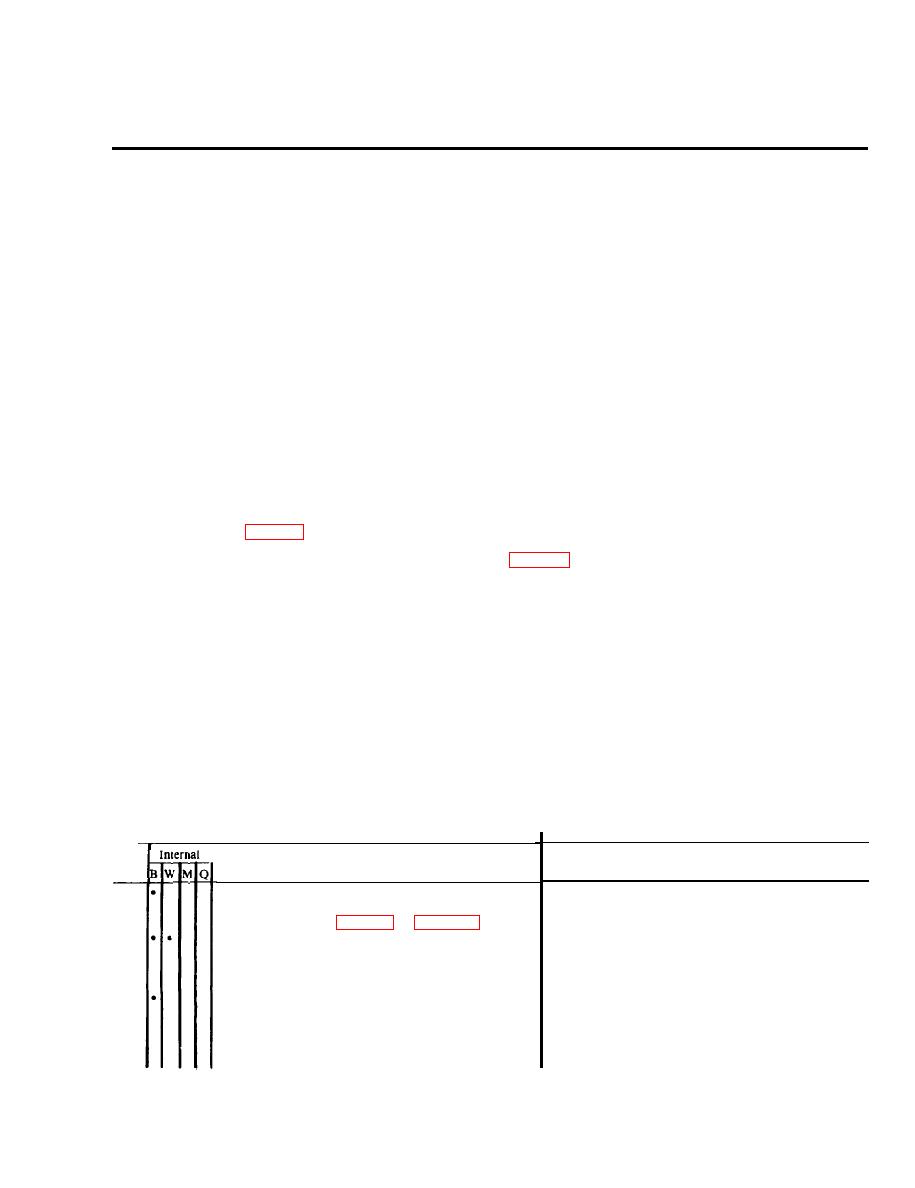

Table 3-I. Operator/Organizational

Preventive Maintenance Checks and Services

Q--Quarterly

M--Monthly

W--Weekly

B--Before

Item

Equipment will be reported not ready if:

Item to be inspected procedure

no.

1

Any item is missing and replacement item is not immediately

Check to ensure that equipment, including accessory items,

available.

is complete. Refer to figure 1-1 and appendix B.

EXTERIOR SURFACE

2

Inspect exterior surfaces, with cover removed, for dust,

moisture, and corrosion. Clean as necessary (paras. 3-6 and

3-7).

CONTROLS AND INDICATORS

3

Check for missing, broken, or loose control knobs.

Operation of the test set is impaired by faulty or intermittent

Check the mechanical action of each control for binding or

control functions or inoperative or inaccurate meter.

excessive looseness. Check the meter for a bent or sticking

needle.

3-1