TM 11-6625-2629-14&P

defective modulation meter is to sectionalize the

support troubleshooting chart contains symp-

fault. Sectionalization means tracing the fault to

toms which will aid in localizing trouble to a

a major circuit responsible for the abnormal

component part.

(4) Intermittent troubles. In all tests, the

operation. The second step is to localize the fault.

Localization means tracing the fault to a defective

possibility of intermittent troubles should not be

component which is responsible for the abnormal

overlooked. Usually, this type of trouble can be

condition. Some faults may be located by sight;

made to occur by tapping or jarring the equip-

ment. Check the wiring and connections to the

however, the majority of the trouble must be

located by checking voltages and resistances.

parts of the modulation meter (fig. FO-3).

b. Sectionalization. The modulation meter

CAUTION

consists of five main sections: the local oscillator,

Do not attempt removal or replacement of

t h e intermediate frequency amplifier, the

parts before reading the instructions in

discriminator, the audio amplifier, and the power

supply. The first step in tracing trouble is to

7-7. Checking Filament and B + Circuits for

locate the circuit or circuits at fault as follows:

Shorts

(1) Visual inspection. Visual inspection will

a. When to Check. When any of the following

help locate faults without testing or measuring

conditions exist, check for short circuits and clear

circuits. A 11 meter readings and other visual signs

the troubles before applying power.

should be observed and an attempt made to

(1) When the modulation meter is being

sectionalize the fault to a particular section.

serviced and the nature of the abnormal symp-

(2) Operational tests. Operational tests

toms is not known.

frequently indicate the general location of trouble.

(2) When the abnormal symptoms reported

In many instances, the tests will help in deter-

from operational test (para 3-4) indicate possible

mining the exact nature of the fault.

power supply troubles.

c. Localization. The tests listed below will aid

b. Conditions for Test.

in isolating the trouble. First, localize the trouble

(1) Remove the dust cover.

to a single stage or circuit, and then isolate the

(2) Remove all tubes from their sockets.

trouble within that circuit by voltage, resistance,

(3) Remove the power indicator lamp.

and continuity measurements.

c. Measurements. Use the multimeter and

(1) Signal tracing. Signal tracing (para 7-10)

make the resistance measurements indicated in

will help in isolating the fault to a specific stage.

the following chart. If abnormal results are ob-

(2) Voltage and resistance measurements.

tained, make the additional isolating checks

Abnormal voltage or resistance measurements

outlined below. When the fault y part is found,

may pin-point a fault, Use resistor inductor, and

repair the trouble before applying power to the

capacitor color codes (fig. FO-1) to find normal

unit.

readings and compare them with reading taken.

(3) Troubleshooting chart. The general

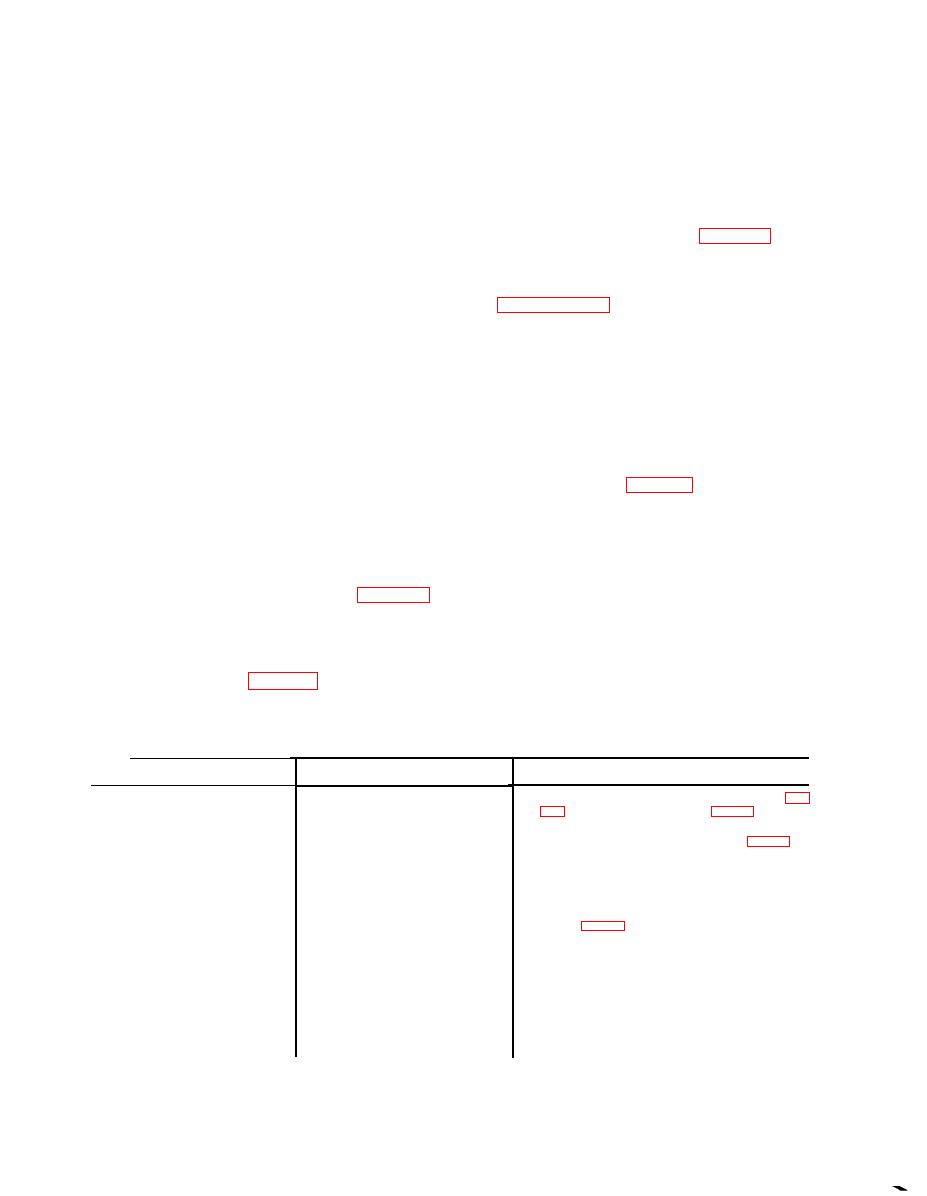

Table 7-2. Resistance Measurements

---.

Isolating procedure

Normal indication

Point of measurement

be

B e t w e e n ground and pin 9 of

Resistance

If resistance is zero, check for short at XV13 (fig.

should

XV13.

approximately 36 ohms.

on the oscillator. If the resistance is infinite,

check for open resistor R131 on TB6 (fig. 7-2).

Infinite resistance.

B e t w e e n ground and pin 4 of

If a short or finite resistance is read, check the

XV16.

wiring to and at sockets XV15 ami XVIG (fig. 7-

2).

B e t w e e n ground and pin 9 of

If a short or finite resistance is read, check the

Infinite resistance.

XV10.

wiring to and at sockets XV10, XV11, and

XV12 (fig. 7-2).

Resistance

be

Between ground and the junction

should

If resistance is zero, check for shorted filter

approximately 250K.

of C101A and C102. Be sure of

c a p a c i t o r C101A or C102. If resistance is

meter polarity to obtain correct

approximately 110 ohms, check for short in

reading. (The higher of the two

C103. If resistance is approximately 165 ohms,

readings is the correct one. )

check for short in C101 B or bypass capacitor

Note: If using the TS-352(*)/U,

C50, If any other resistance below 250K is

the lead connected to the OHMS

observed, check all the bypass capacitors (fig. 7-

connector should be grounded.

3 and FO-2).

7-2