TM 55-4920-231-14

(12) Symbols. The symbol O, F, or H, placed in the appropriate column indicates the level re-

sponsible for performing that particular maintenance function. The symbol "%%" which applies to

organizational maintenance indicates the particular maintenance function may be performed provided

it is specifically authorized by the direct support maintenance officer. Use of the symbol will apply

only to replacement of major assemblies and time-consuming operations which are within the capabil-

ities of organization, but over which control by the commodity commands is considered essential. In no

case will the direct support maintenance officer require the accomplishment of a "%%" maintenance

function by an organization or unit, and in no case will a "%%" function authorize stockage of parts

at organizational level.

d. Column 4, Tools and Equipment. This columm will be used to specify, by code, those tools and test

equipment required to perform the designated function.

e. Column 5, Remarks. Self-explanatory.

3. GENERAL.

a. A maintenance function assigned to a maintenance level, which for any reason is beyond its capa-

bility, becomes the responsibility of the next higher maintenance level.

b. The authority to perform a maintenance function does not constitute authority to requisition or

otherwise secure necessary repair parts as specified in current supply directives.

4. DEVIATIONS.

a. Normally, there will be no deviations from the assigned maintenance level. In cases of operational

necessity, a maintenance function assigned to a maintenance level may, on a one-time basis and at the

request of the lower maintenance level, be authorized to the lower maintenance level by the mainte-

nance officer of the level to which the function is assigned.

b. The furnishing of special tools, equipment, and the like, required by the lower maintenance level

to perform this function, will be the responsibility of the level to which the function is assigned.

5. ADDITIONAL INFORMATION.

a. Changes in the Maintenance Allocation Chart will be baaed on continuing evaluation and analysis

by responsible personnel and on Maintenance Request Forms DA 2407 received from field activities.

b. All maintenance prescribed herein will be performed in accordance with applicable publications.

c. In any instance of conflict with current tool and equipment lists or current supply manuals, this

Maintenance Allocation Chart will be the final authority. Each such instance should be promptly re-

ported by Maintenance Request Form DA 2407.

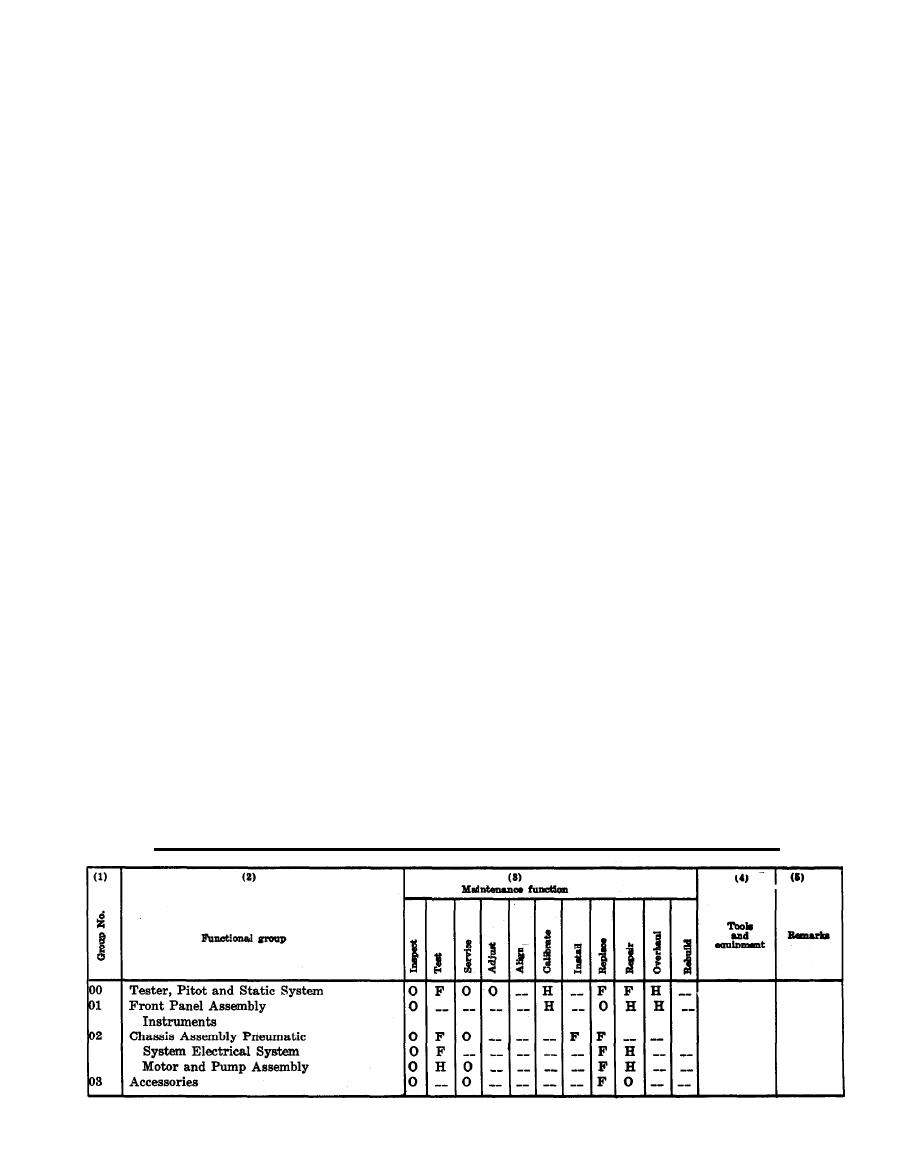

MAINTENANCE ALLOCATION CHART

FOR

TESTER, PITOT AND STATIC SYSTEM

62